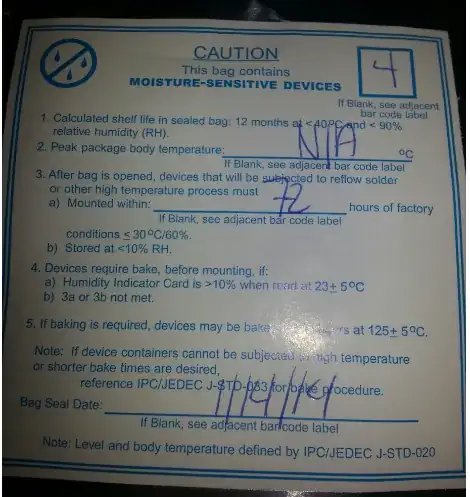

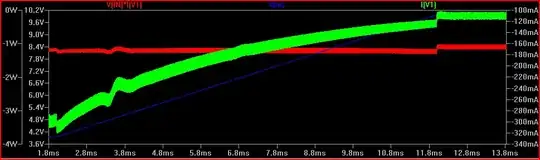

In general, the reason for baking a component is to carefully remove all the moisture from the plastic part of the component. When a SMT component goes through a reflow oven, the temperature of the component (obviously) rises very quickly, causing any moisture inside to turn into steam. This expansion of water vapor can crack the component, resulting in an unusable or crippled board.

As indicated in Matt's answer, some components are more sensitive to moisture absorption than others. Once components have absorbed too much moisture, it is a very tedious process to remove the moisture, usually requiring 24 hours or more in a special baking machine. Some of these machines bake the parts in a vacuum chamber, etc.

However, if you are just hand-soldering prototypes, there is nothing to worry about. The component body will not get hot enough to vaporize the moisture inside. Unfortunately, many ICs requiring baking are QFNs, BGAs, and other components that cannot be properly hand-soldered.