There are many things that can cause a variation in a resistors resistance.

For the specifics of the OriginalPost IF a +-5% resistor actually was +3.5%, it will not, between operations change +2, -3% ... PURELY based upon tolerance.

Now there are other influences on such parts that do cause variation.

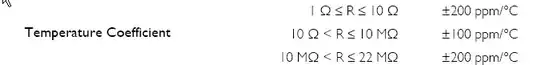

One is temperature not only from the local ambient (and thus similar resistors would additionally vary by the same amount) but from their own self-heating (a resistor operating at 99% power rating will obviously have a slightly different resistor value from one that was operating at 1% power rating.

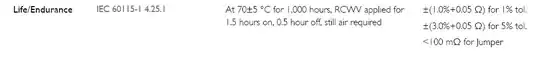

There is also ageing which is related to temperature (rule of thumb we use is a 80% continually stressed 1% will be 4% over 25years, a 0.1% will be 0.2% for <50% stress over 25years) . Any decent resistor manufacturer will tell you all the information you need to know

Here is a good place to start.

http://www.vishay.com/docs/49562/49562.pdf

My advice if you have a bunch of voltage dividers is to create a spreadsheet and have a column per resistor.

Have different rows that then go:

MIN from tolerance ( ie R *0.95)

MAX from tolerance (ie R *1.05)

MIN_TEMP_MIN_RES ie TCR equ at min temp and lower tolerance

MIN_TEMP_MAX_RES

MAX_TEMP_MIN_RES

MAX_TEMP_MAX_RES

Then for the three temperatures (min, ambient, max) take the worst-case voltage divider combinations (upper_max & lower_min, upper_min & lower_max) ...

for 5% resistors you will not get an overall accuracy spread better than 10% (just bear that in mind)