I'm looking for a way to build a cheap 1m linear encoder. Precision should be around 2cm (which is not really "precision").

Any advice will be welcome.

@Joe Hass : yes it is moving. Not really fast. Speed is not a concern. 1m per 10s is ok.

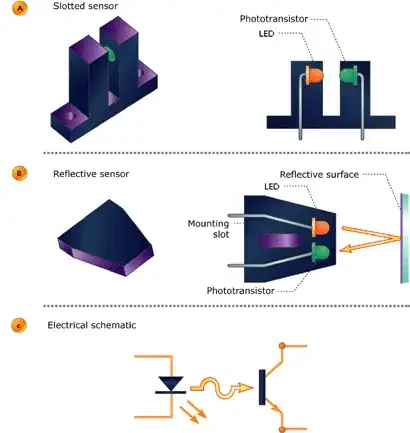

Edit : Thanks for help, as asked I give more details. The device will pick paper in drawers arranged vertically. There's one moving paper picking device, and dozen of drawers on top of each others. I need accuracy to locate the drawers to pick from. And a good notion of speed and position for the PID system that control the picking device. I think two laser cut optical rulers will do the trick. (there's a fablab in my city).