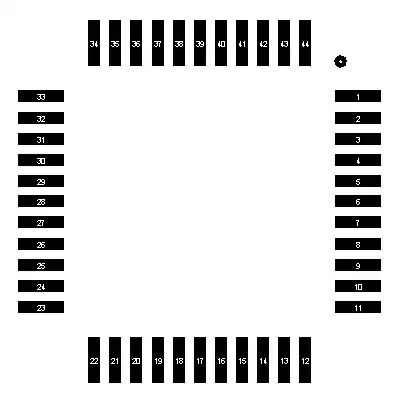

Sometimes when I order PCBs from a board house, I omit the bottom silkscreen for budgetary reasons. When I place surface-mount chips on the bottom of the board, I then end up with a footprint that doesn't indicate the chip orientation. This is annoying because it means that I need to verify the component placement and orientation during assembly, and this allows for errors when placing the parts.

How can I clearly indicate pin 1 with the remaining layers in a way that will be clear but not significantly impact the PCB size or cause issues when soldering? I'm assuming that I always have access to a solder mask layer and a copper layer.