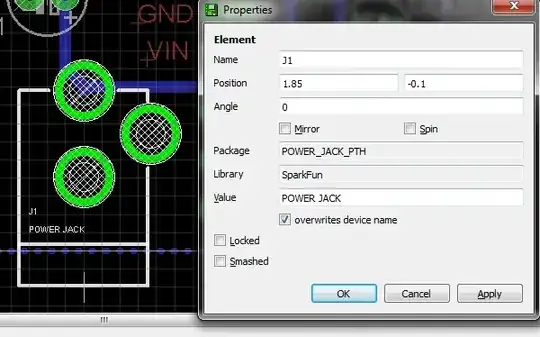

I am wondering how I can include a DC jack such as below in my PCB circuit:

There are no such PCB packages in my library, so the first step, I presume, is to make a prototype with the exact dimensions as in the datasheet (correct me if I'm wrong).

What I am really confused about however is how to drill the holes in the PCB, given that I need a rectangular section instead of a circular one, for the three pins.