I'd like to build a tiny RC car that can run indefinitely without the need to charge. Bumper cars have strips of power on the ground and according to Wikipedia this is how they work:

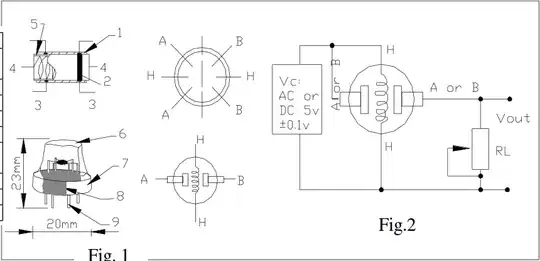

"Uses alternating strips of metal across the floor separated by insulating spacers. The alternating strips carry the supply current, and the cars are large enough so that the vehicle body can always cover at least two strips at any one time. An array of brushes under each car make random contact with whatever strip is below, and the voltage polarity on each contact is sorted out to always provide a correct and complete circuit to operate the vehicle."

Has anyone attempted this before on a smaller scale? I'm not quite sure the circuit required to achieve this on a 5V~ scale, and the type of "brushes" that would be required. Any links or direction would be greatly appreciated thank you!

Edit: Alternatively I'd love if anyone had any ideas on how to keep a power cable directly above a car as it moves around a closed space (so if there were multiple cars they couldn't tangle on each other's wires).