At the end of the day you have to realise an Electrical Machine is basically an electrical energy to mechanical energy converter that utilises magnetic fields as the link.

The magnetic field/flux is either generated by magnetics or via electromagnets.

Motors in general have always been a difficult subject that I cannot

fully wrap my head around. Considering DC motors, what determines the

rate at which the motor spins?

The rate the electrical machines rotor will spin is fundamentally the same for all electrical machine types (Induction, sync, SR, BLDC, BLAC, brushed, hysteresis ...).

The rate of change of flux.

How this rate of change is created is very specific to each machine.

But basically by creating a magnetic flux on the stator & the rotor, the rotor will attempt to align itself just like magnets do.

This Electro-magnetic torque manifests itself as mechanical torque (due to being perpendicular to a freely rotating axis)

A torque acting on some inertia results in an acceleration that would want to take the rotor to infinite speed.

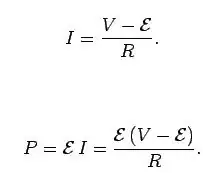

It can't because of Lenz's law. You now have a rotating magnetic field passing by coils, this induces a voltage which opposes the voltage source you are using to force current into the electrical machine to generate a magnetic field to produce EM_Torque.

The faster you go, the higher this voltage, the more it opposes the voltage source you are using. At some point you are no longer able to force current into the windings to create a magnetic field => no more EM_Torque --> no more rotor torque --> no more acceleration.

You have now reached your maximum unloaded speed.

As mentioned different machined create the changing flux by different mechanism

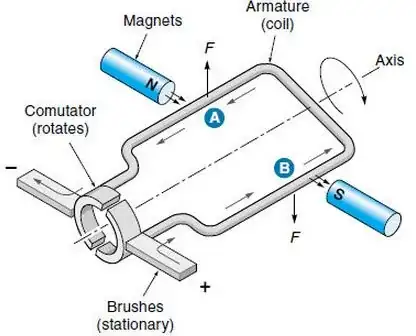

- Brushed Machine (DC stator DC rotor)

PM stator & a wound rotor, brushes are used to transfer electrical power to the rotor to create a DC current and thus a unidirectional magnetic field on the rotor. Apply the voltage source and the rotor will turn to align itself. This causes “commutation” to occur via the brushes and the rotor magnetic field is changed pushing it away from the present stator pole & attracting it to the next.

More voltage ==> more EM_Torque ==> Faster commutation

- Syncrounous Machine (AC stator DC rotor)

Wound rotor, Wound stator. Power is usually transfered to the stator via a Main-Exciter (basically a rotating transformer) and it produced a DC current in the rotor that does not change direction.

The Stator is then excited with an AC voltage source.

The rotor will “lock onto” this varying stator field and will be essentially dragged around with it. To increase the speed of a Synchronous machine the frequency of the voltage source to the stator is changed: Higher == Faster.

- BLAC, BLDC (AC stator, DC rotor)

These are basically just Synchronous machines but they have permanent magnets on the rotor. Higher the stator frequency the higher the rotor speed.

AC & DC just comes from the type of current control that is used.

- Switched Reluctance (AC stator ... rotor)

Beautiful machines, salient rotor NO WINDINGS, NO FIELD GENERATION. Wound stator. The stator is excited to produce a flux. An unaligned rotor will experience reluctance torque and attempt to align itself to minimise the reluctance in the present magnetic cct ==> mechanical torque ==> acceleration. Once alignment occurs you stop firing the stator and let the rotor “coast” for a short period before firing again

- Induction machine. (AC stator, AC rotor)

Wound stator, wound rotor. Unlike a synchronous machine however, the rotor windings are usually shorted (creating a squirrel cage like construction). Applying an AC voltage to the stator creates an AC magnetic field. This induces a voltage on the rotor & because it is shorted produces a current which in turn creates a magnetic field to be dragged around by the rotating stator field