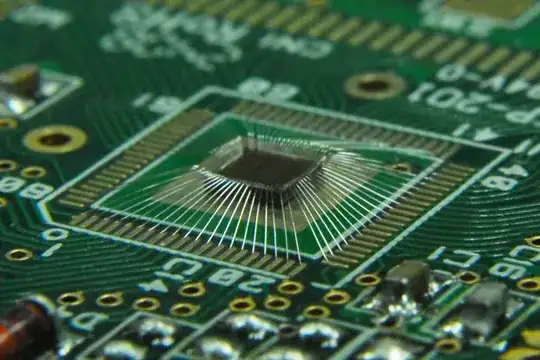

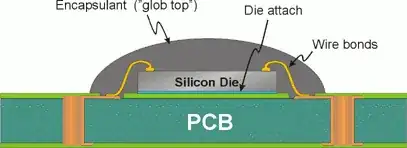

Like Leon said the techniques is called Chip-on-board (COB). You do exactly the same to bond the die directly to the PCB as you would to bond the pins in an IC package. Savings: no package needed. (You could say no soldering also, but that has to be done anyway, so that's not really something you save on).

COB is not cost-effective for small series, and with a few exceptions you will only see it on mass-produced products (100k~1M/year).

The blob is an epoxy resin to protect the IC with the bonding mechanically; the bonding wires are very thin (as thin as 10\$\mu\$m for gold wire) and therefore extremely fragile. Another form of protection it offers is reverse engineering protection. This is not fool-proof (the resin can be removed), but it's a lot harder to reverse-engineer than simply desolder an IC.

IP protection example: until a few years ago FPGAs always needed an external serial memory to load their configuration from. This configuration could be an almost complete product design, and therefore expensive. Yet, simply by tapping the communication between FPGA and configuration memory everybody could copy the design. This can be avoided by COB-ing FPGA + memory together under a single epoxy blob.

note: the die in a BGA is also bonded on a thin PCB, which routes the signals from the edges of the die to the ball grid at the bottom. This PCB is the base of the BGA's package.