I want to use a servo taken by a radio-controlled car. However, I found out that wheels' rotation (front wheels) is not performed by a servo, but from a motor to move the wheels and a mechanism for control, into a steering box.

Specifically, there are 2 wires (red/black) that connect controller board with a motor. Motor communicates with a set of gears.

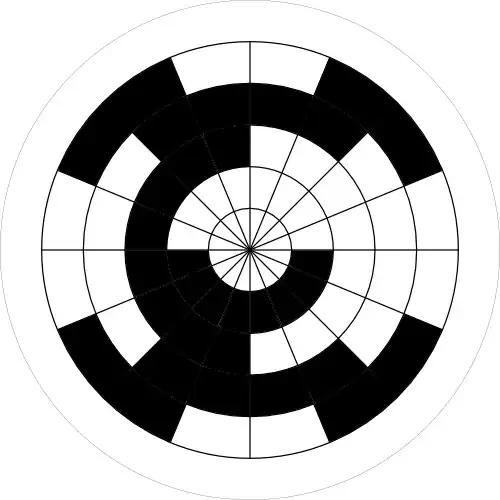

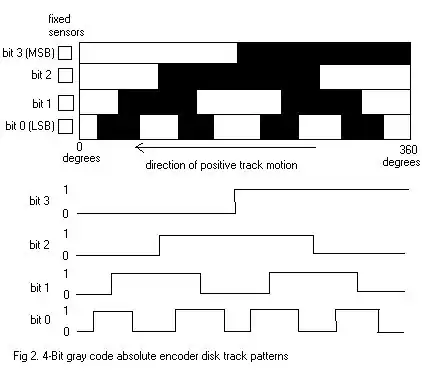

Control (this is the part I can't figure out) is performed by 4 wires, that end up to a simple circuit. Depending on which wire transfers electrical current, it's conductive area has current too. Set of gears that motor communicates with, connects to this circuit with 4 metallic cyclic endpoints.

Does anyone know how exactly control is performed? Is important to decode the operating mode, as I intend to use mechanism for another implementation.