I have a transparent project box encasing my breadboard with an LED on it. I want to use this LED to make the whole top of the box glow uniformly. Does anyone have any ideas? I tried using soft plastic, about 4 mm thick and drilled a whole halfway through it for the LED. Even after using sandpaper, you can still clearly see where the LED is, and the illumination is a quarter of the box, at most. The box is about 5x7 cm.

-

2Use edge illumination and frost the whole panel http://www.instructables.com/files/deriv/FVG/LM7I/H7432HB0/FVGLM7IH7432HB0.LARGE.jpg :) – HL-SDK Oct 28 '13 at 19:18

-

1If you *need* it to glow absolutely *perfectly* uniform then you may need to use a EL panel instead (and hope that the panel doesn't have any non-uniformities). – Ignacio Vazquez-Abrams Oct 28 '13 at 19:21

-

2Absolutely uniform glow isn't a requirement. "Sorta, kinda uniform" will do just fine. – David Högberg Oct 28 '13 at 19:33

-

1Web search for "edge lit" and "edge lit perspex. Using several SMD LEDs around the edge of a plastic sheet and edge lighting will give an reasonable result. Even a single one can work reasonably well with due care. – Russell McMahon Oct 28 '13 at 19:48

-

[Images for "edge lit"](https://www.google.co.nz/search?hl=en&site=imghp&tbm=isch&source=hp&biw=1920&bih=1032&q=%22edge+lit%22&oq=%22edge+lit%22&gs_l=img.3..0l10.2675.5896.0.6159.10.10.0.0.0.0.270.1975.2j1j7.10.0....0...1ac.1.29.img..2.8.1455.h4rGypWCwtc) – Russell McMahon Oct 28 '13 at 19:49

-

Images for ["edge lit" backlight](https://www.google.co.nz/search?hl=en&site=imghp&tbm=isch&source=hp&biw=1920&bih=1032&q=%22edge+lit%22&oq=%22edge+lit%22&gs_l=img.3..0l10.2675.5896.0.6159.10.10.0.0.0.0.270.1975.2j1j7.10.0....0...1ac.1.29.img..2.8.1455.h4rGypWCwtc#hl=en&q=%22edge+litbacklight&tbm=isch) - many ideas. Some may even be good ones :-) – Russell McMahon Oct 28 '13 at 19:52

-

[A commercial product](http://www.knema.com/pages/edge-lit-led-panels) and [another one](http://www.elumanation.com/LED_Light_Panel.html) – Russell McMahon Oct 28 '13 at 19:53

-

1As @RussellMcMahon has said, a single one can work, especially if you use mirrored (like aluminum foil) tape on the edges with a finished polished edge. Allows for more refraction of the light. – Passerby Oct 28 '13 at 21:09

1 Answers

I do a lot of lighting projects for props, theater, and holidays (like Halloween). "Glow" effects are frequently wanted, so you have to diffuse the light source in order to avoid having the point source visible.

There are several ways that I do this, so I'll just list some of the techniques here:

- Diffusers: Depending on the type of light, not all diffusers are appropriate. You can use paper (generally tracing or "onion" paper), tissue, cotton, acrylic, mylar, cloth, etc.

- Dispersion or Viewing Angle: LEDs can be purchased with different dispersion patterns. Some have a dispersion angle of 90 degrees or less, which is not ideal for glow effects. You can look for LEDs that have a dispersion angle of more than 90 degrees, or take the LED to sandpaper to "soften" its focus.

- Reflection: Arrange the light so that viewers are seeing its reflection from a surface rather than from the light source itself. For example, an LED might point "backwards" at a surface that is painted or coated with a light-diffusing paint or material.

- Distance: This applies to diffusers, but is also somewhat of a separate point: The more distance between a light source and the observer, the softer the light (generally). If you place a diffuser (such as a translucent acrylic sheet) over an LED, you will still observe the bright point unless the LED is moved a few cm away from the sheet. As the distance increases, the light has more chance to spread and appears softer. However, depending on the viewing angle of the light source, the center will still appear brighter.

- Electroluminescent panels/wire: EL panels and "wire" emit a softer glow, and can be useful if a bright light is not needed.

- Fluorescent tubes: Cold Cathode Fluorescent Tubes/Lamps (CCFT/CCFL) are generally brighter than EL panels and are useful for achieving a glow effect.

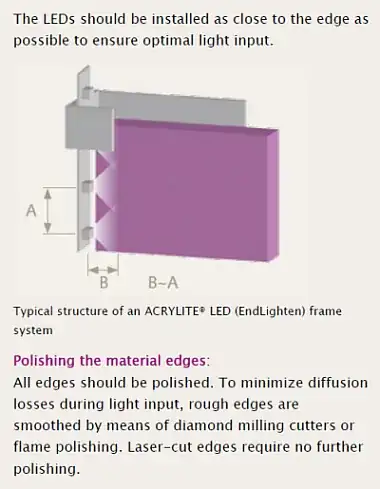

- Light pipe/Edge lit: Many plastics or acrylics can be used to channel light. Manufacturers make "light pipes" so guide light from an LED to some other place, like a front panel. A side effect is often that light bounces in the "pipe" and appears more uniform on the display surface. While a "light pipe" is probably not something you'll use unless you're designing for a major product, "edge lit" panels are definitely available. One such example (and others from comments) is a product called "Acrylite EndLighten" made by Evonik Industries.* This sheet can be edge lit, and emits a fairly uniform glow.

Edit:

For those curious, based on comments, here is the link to a datasheet for the Acrylite Endlighten product. I'm sure other products designed for edge-lit glow applications are similar.

The product specifically calls for non-diffused LED light sources, to minimize losses injected into the material. Here's an excerpt:

The main feature of such an acrylic sheet is that it has small particles suspended in it which diffuse the light and "throw" it perpendicular to the source. You can achieve similar glowing effects with a translucent "soft white" acrylic sheet, but obviously this product is designed more specifically.

* I am not affiliated with Evonik Industries in any way.

- 32,302

- 33

- 134

- 249

-

When you say "edge lit", does that mean you have to drill a hole into the plastic (e.g. Acrylite) and insert the LED, or is it sufficient to have the LED close to the edge? – David Högberg Oct 28 '13 at 20:20

-

If the edge is polished and clear you don't need to drill a hole into it. (In fact, if you drill a hole, you *still* need the surface to be clear and polished to inject light properly.) It's usually sufficient to have the light source touching or at least very close. – JYelton Oct 28 '13 at 20:22

-

-

If you are edge-lighting something like Acrylite, clear LEDs work fine. We often use a framing strip so that the very edge is not visible. For other applications, your mileage may vary (YMMV) but diffused LEDs will produce softer light to begin with. – JYelton Oct 28 '13 at 20:26

-

@JYelton no, an unpolished edge would work better for the edge, because of led viewing angles. An unpolished edge will diffuse the light better, no? – Passerby Oct 28 '13 at 21:11

-

1@Passerby In the case of Acrylite (EndLighten, specifically), we've seen very little difference whether the LEDs are diffused or not. The edge shows somewhat the dispersal pattern of a clear LED (brighter triangular areas) but the overall glow from the panel is very consistent beyond a few cm from the edge being lit. We have been using 5050 SMD RGB LEDs with a very wide (135 degree) angle with good success, but they are not by themselves diffused. With these LEDs we cover about 3 cm of the edge in framing material. (We are using large sheets, about 1 meter wide from the lit edge.) – JYelton Oct 28 '13 at 21:50

-

@JYelton Its hard to give an upvote for the update when I already voted the original up. Nice answer either way. – Passerby Oct 29 '13 at 02:10