Sorry I don't have a way to illustrate this, but here goes ..

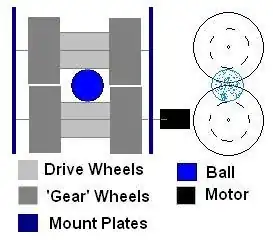

Assume your two ball-launching wheels are in a horizontal plane. Now imagine that the DC motor is under one of the wheels, with its shaft also horizontal, but in line with the two ball-launching wheels' centers, so if you put a small wheel on the motor's shaft, it will be upright. If this small wheel contacts one of the ball-launcher wheels, it will drive it, sort of like a bevel gear. From here, you should be able to see that if you put two such drive wheels on the motor shaft, such that each contacts one of the ball-launching wheels, just either side of the gap between the launch wheels, then the launch wheels will turn in opposite directions, i.e., in the gap, the rims of the launch wheels will go in the same direction, thereby projecting the ball out of the gap.

Well, ok, here's some questionable ascii art. You are looking at the business end of the machine, the ball comes at you from where the '*' is. The launcher wheels are seen horizontal, rim-on, on top, and the drive wheels are also seen rim-first, but are vertical and below.

=====|===== * =====|=====

-|-----|--[motor]

Note that if you do it this way, you can vary the relative speeds of the launch wheels by varying the contact points with the drive wheels. If one drive wheel is 10cm from the axis of its launch wheel, and the other drive wheel is only 9cm from the other launch wheel axis, the ball will get some side-spin.