I have AD811 in my application that works just fine but as it is working in +/-15 v supply at around 14.5 mA, it's power is around one third of watts. It is hot when touched. I checked if this is a malfunction in this website and contacted Analog Devices Technical support and I am sure that this is a normal behavior of this device.

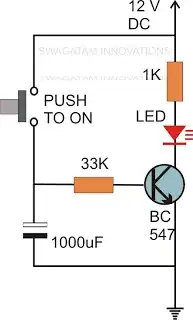

Now I am thinking about a cooling method for this device but as this DIP package has no where to attach a heat sink, I thought about some options like these ( regarding the device works in high frequency up to 50MHz):

Using a fan: fan's motor may impose some noise

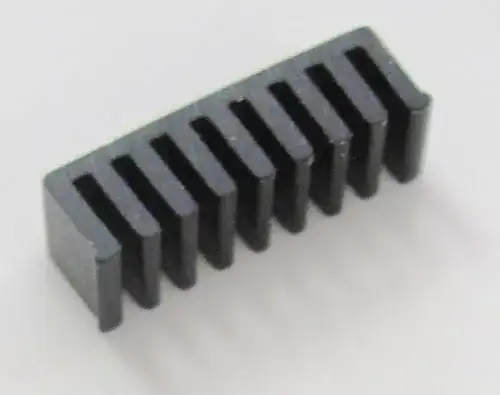

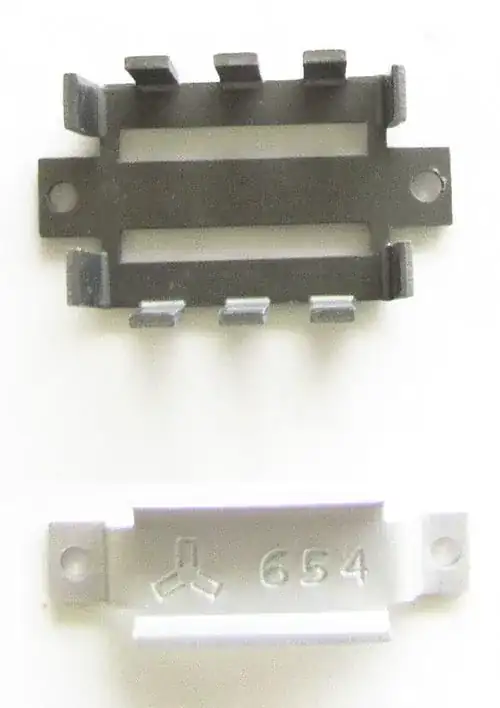

Putting a flat heat sink on top of the device , attaching it with silicon paste and grounding it

Using a thermoelectric coolant element.

I have never heard about cooling methods for DIP packages especially in high frequencies, I want to know if there is any standard method for that.