I guess it's a real problem trying to standardize on connector size/shapes for different DC supplies - what to do the with AC supplies as well?

The op has "smoked" equipment that cost hundreds of bucks by mistakingly plugging in a 12V dc adapter instead of the 5V adapter and I can't understand why the expensive equipment didn't use a fuse and zener to protect itself.

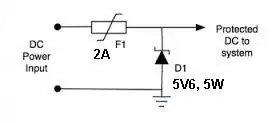

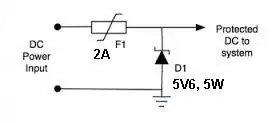

Providing that the equipment running nominally from 5V took no more than 1.5A (and 2A under overload) the values shown would work: -

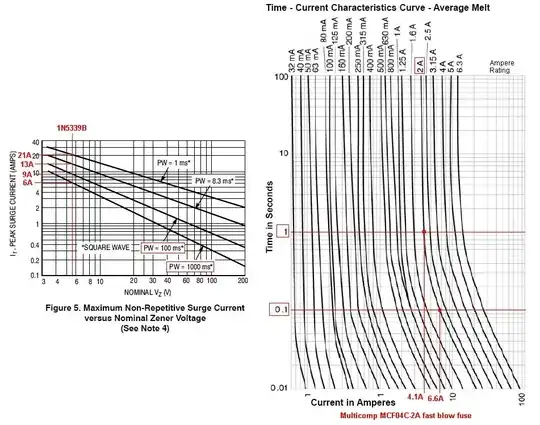

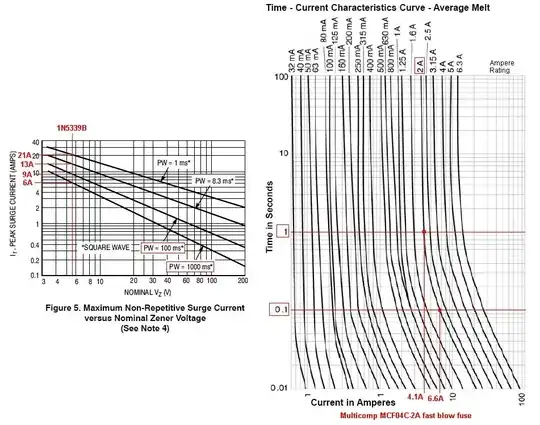

To the left above there is the time limit graph of the 1N5339B 5.6V 5W zener diode and to the right is a typical characteristic of a 2A fast blow fuse. It can be seen that the zener can take 6A for 1 second or 9A for 100 ms, whereas the fuse gives up the ghost at 4.1A in one second and (for comparison) 6.6A in 100 ms. This on all but the worst days means the zener will survive and the fuse will blow. It's a little close but I'm trying to demonstrate the principle and my earlier guess at values is about right. Thanks to supercat for reminding me I needed to justify this.

A zener would also offer some protection against the power being applied in reverse (all barrel connectors do not observe same polarity).

Different values will suit different applications of course.

There are better circuits that can take bigger overloads such as crow-bar circuits but my point is made and my deapest sympathies to the OP's wallet!