What's a canonical method for reducing / eliminating electrical noise induced in ADC from a small brushless DC fan? For reference below, I'm also using this wall-wart and this 5V linear regulator.

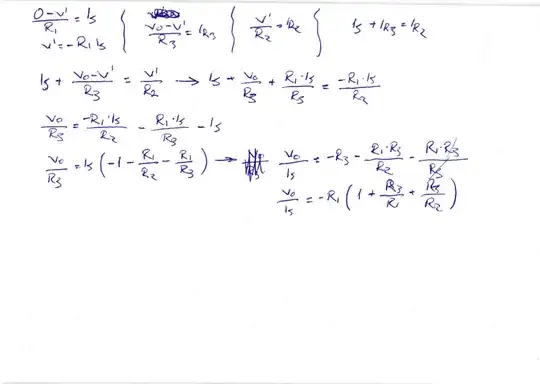

My baseline system looks like this:

I have some options in my head and I'm wondering what the best one might be.

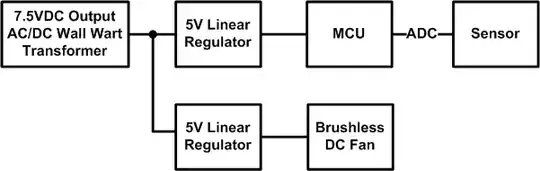

My first idea is this [OPTION A]:

My second idea is this [OPTION B]:

My third idea is this [OPTION C]:

There are probably other options that I haven't thought of, as well as permutations and combinations of these options. What are the merits and drawbacks of these options? What option would you choose and why?