Reed switches can stick for the following reasons:

- The metal of the contacts have been pitted or otherwise compromised, from arcing if switching with active loads

- The contacts have become magnetized (or another magnetic field is unaccounted for)

- The reed switch is physically damaged, such as through bending or cutting the leads improperly

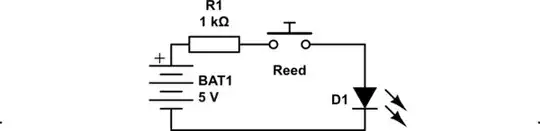

Current Rating:

4mA doesn't sound like much current, even for switching. The lowest rated switching current value for reed switches I could find at Digikey is 50mA.

A reed switch has two values for current rating. Switching and carry. Switching is the amount of current that it is designed to switch on and off without harming the contacts. Carry is the amount of current for a switch that has already been engaged, and thus won't arc when switching.

Nickel and iron used for the contacts are soft metals, which means they more vulnerable to melting. So the contacts are generally plated with a harder metal (like rhodium or ruthenium) to increase the life of the switch.)

Residual Magnetism:

Reed switches are made of metal contacts that have been annealed, a process that leaves no or very little magnetic retentivity. This means after the reed switch is removed from a magnetic field, there should not be any residual magnetism in the contacts. (Meder)

It's possible the reed switch is defective and is not properly annealed, causing residual magnetism problems.

Physical Damage:

Reed switches are manufactured with fairly exacting tolerances. When cutting or shaping the leads, it's possible to damage the reed or glass. Meder has a whole document dedicated to handling precautions. In short, physical damage may be difficult to verify visually, but can affect performance. An excerpt from the linked document:

Internal damage can occur with no visible signs on the seal. In these instances, seal stress has occurred, leaving a torsional, lateral, or translational stress in the seal. This produces a net force on the contact area that can affect the operate characteristics (Pull-In and Drop-Out), contact resistance, and life characteristics.

Summary:

Did I manage to magnetize the contacts?

I would say unless the reed is defective (improper annealing) it is unlikely.

Is the current too large (approx 4mA)?

Without the datasheet specifics, unknown. But also unlikely.

Does it matter what magnet you use? Eg. regular versus rare earth.

No, it should not matter. The reed switch contacts simply react to a magnetic field, whatever its origin.