I have recently acquired an electronics component that I was expecting to have a "normal" surface mount foot that I could solder.

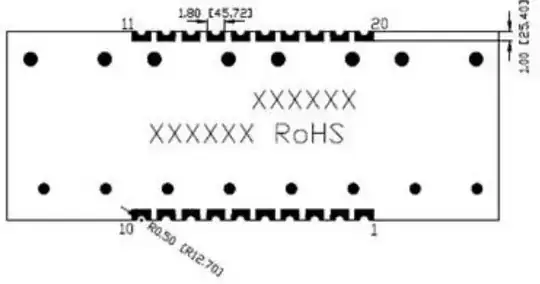

Instead, what is has is a very thick section that has a 0.50mm semi-circular notch (see picture):

What is the appropriate way to mount a device like this? Are the notches designed to take a pin of some kind?

The notches are a standard 2.54mm pitch, and the row spacing is 19mm - I haven't found any kind of socket that would take a component of this size, so I'm assuming it would need to be soldered directly to the PCB?