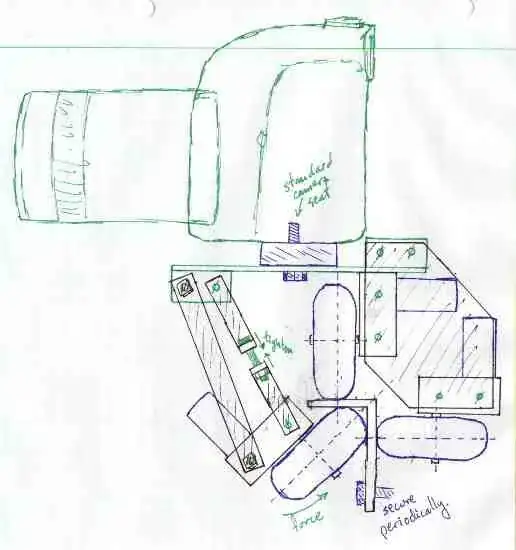

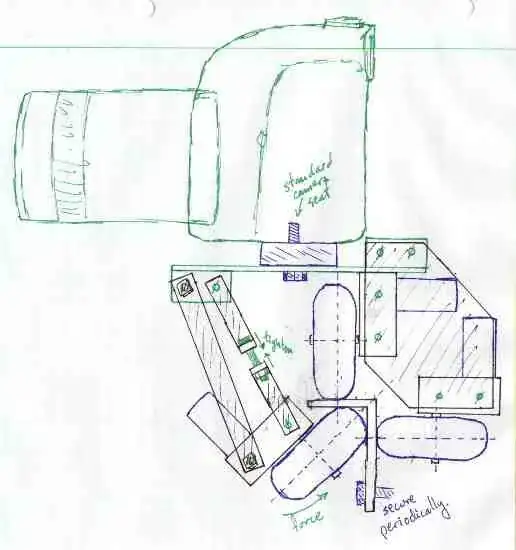

Here's what I would do with my 35-mm camera if I needed it to travel along an accurate trajectory, and consider it to be simple to customize to a specific trajectory and stable enough for a heavy camera. Use a strip of 1/16" to 1/8" thick, 3/4" by 1.5" angle-iron to go from point A to point B, bending to whatever vector you wish at different lengths -- it's possible to bend this by hand (or over your knee). You would need to construct a trolly to grip the track. There are a zillion different ways of doing this; here is one:

(source: tyblu.ca)

I've put in servo-motors (mounted on gearboxes), but you could use stepper motors. A brake is a chock or wedge shoved under the wheel by a solenoid or spring -- the spring would save you a solenoid, but make the trolley 1-way only. You may not need every wheel to be powered. Also, once one has a trolley they can mount whatever they want however they want on it, so long as it can support the weight and torque. Those Gorilla camera stands look like they could be mounted then positioned arbitrarily. If you really want to get fancy you could give the camera degrees of motion like pan, tilt, and roll.

Path length or position can be tracked in a number of ways; here are some: rotary encoder, using a pre-marked disk attached to one of the shafts, an LED and a photodiode; optical mouse sensor, sensing either wheel rotation or relative angle-iron movement; feedback from servo motors. Note that if resultant travel from incremental motor actuation is well defined, you may be able to deduce total travel and not have to track the path.

I'd fight with myself between this solution and parallel threaded rods. I've used ready-rod before, and it's really easy, but it would be more difficult to secure it, as you could only do it at the ends, whereas this one can be secured along its length.