To prevent stranded wires from unpacking and changing diameter when the insulation is removed, first strip off about an inch or so from the end of the wire you want to measure, then strip another quarter inch of insulation without removing that piece from the end of the wire. Leave about a quarter inch gap of bare wire exposed between the insulation pieces - just enough to get a caliper gauge in for measurement. The insulation keeps the wire strands captive on both sides of the measured section, helping to prevent untwisting, unpacking, or squishing the wires together into an oval shape while measuring. Don't squeeze the caliper too tight when measuring.

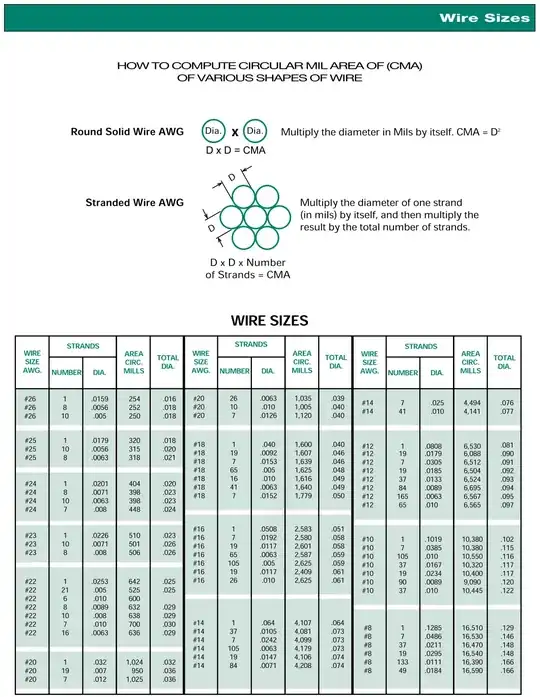

Stranded wire diameters can vary quite a bit, depending on things like the number of strands, amount of twist and manufacturing processes. While tables exist on the web listing diameters for various stranded wire gauges, those tables vary quite a bit. If you know the manufacturer of the wire in question, go to their website for more accurate information. If that is not possible, then you will have to guess-timate where the measurement falls into the various lists on the web. If you must be absolutely positive of the correct answer, then you will need to get a micrometer, and follow the methods described above.