I'm using some transistors in SOT-23 packages, designing a board in KiCAD 7.

- NXP's recommended footprint has pads 0.6 x 0.7 mm. Datasheet

- Vishay's "recommended minimum" has pads 0.559 x 0.725 mm Datasheet

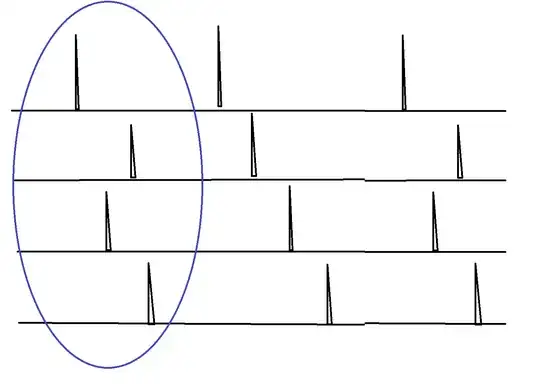

- KiCAD's pads are much bigger 0.6 x 1.475 mm (

Package TO SOT SMD:SOT-23) - KiCAD's "handsolder" variant even bigger: 0.8 x 1.9 mm (

Package TO SOT SMD:SOT-23_Handsoldering)

What advantages are there to such long pads? Can I simply shorten them to, say, 0.8 mm long?

I can only see thermal advantage; as a disadvantage it's making my tracking a little difficult, as I'd like to send a signal up from pin 2 between 1 and 3.