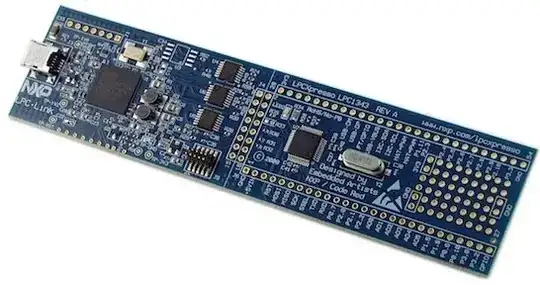

This is the most bad-quality modern computer electronics PCB I have ever seen. And I've seen some fecal matter. This is the fecaliest matter of all.

This board should have been rejected at the factory, and shredded. See how the copper layer throws bubbles? That means it's broken, because not only does the copper layer become unreliable, it also wildly changes the characteristic impedance of the lines, and that's important for USB, and especially for SuperSpeed USB.

Speaking of which: even if this board wasn't damaged, it would be so bad that I'm surprised it worked for your friend so often. I guess that is a testiment to the robustness of USB transceivers, and of the protocols atop of USB's physical layer that can recover when errors happen.

Because this board does everything wrong.

- USB mandates protection diodes on the inputs. None.

- USB DP and DN lines are pseudo-differential and controlled-impedance, but relatively relaxed. The lines on the board are layed out as if these were very slow signal lines (a couple kHz), and not lines that carry up to 480 Mb/s. You cannot just make one wider than the other, because it saves you a dollar on a million devices produced due to less etchant usage. That is just a bad idea, it makes the signal quality worse, without real reason. This is like if someone who built least-quality toys in the 1980s was allowed to design electronics post-2012. Like. What does that person do for a living? Certainly not lay out high-speed PCBs.

- While really bad, this is limited in effect, because that trace is short relative to the signal bandwidth. Much worse, the differential SuperSpeed lines: You cannot reasonable lay them out on a single-sided PCB. It just doesn't work well – your traces become bad to produce and route, because there's no ground plane with which they would form a differential coupled microstrip line with ground, and still need to have the USB-specific characteristic impedance, and your traces need to become very large. And these traces are nowhere close to what a controlled-impedance line should look like: varying in thickness, varying in distance to each other, laid across worst-quality substrate, and deliminating copper… This thing definitely reflects about much signal power back at the transmitter as it lets through.

- There's no current limiting at all. That's plain illegal. Your USB devices should be protected against short.

- Mechanically, these USB connectors aren't even soldered in on both sides. That's just sloppy. And bad.

- The connectors are blue. And according to the USB standard, that means "USB 3 or newer", including SuperSpeed. Now will you look at that: all but the bottom connector only have the USB2 lines connected. This is fraud. Your friend bought a hub thinking it did USB3, whose connectors explicitly state through color "we're USB 3", but only the bottom one is USB3.

In other words, if you gave me that hub, new, for free, I would make sure it gets brought to the correct electronics disposal agencies.

There's nothing to save about it. It was totally broken when it still worked, and I'm happy it finally gave up the ghost, so that the amount of data loss your friend experienced while using it to connect to storage devices was limited.