Trace width matters for current. Spacing matters for voltage. The trace widths used on your PCB for 2 A are not wide enough. I think a bigger problem in your design is track length. For switching supplies you need to consider track inductance for the tracks carrying the switching currents. Track lengths must be minimized.

Besides using an inductor unsuitable for the task (mentioned in the previous post), the layout of the PCB can be better. Unfortunately, the datasheet doesn't give a sample layout like many switching I.C.s do. See if their Web site has a demo board layout. If they don't, pull up some data sheets from more main stream parts and read about what is important in the layout and the example layouts.

You should be using copper pours for the parts that carry the switching currents and minimize distances between parts that carry the switching currents. Also, you need ceramic bypass (around 100 nF) capacitors in addition to the electrolytic capacitors to take care of the fast switching edges. The ground connection needs to be a small area, not spread about with a maze of serpentine traces.

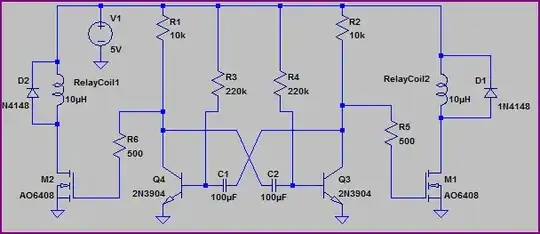

Schematics are generally drawn with the input on the left and output on the right. This makes it easier for experienced practitioners to read and understand the schematic.