I'm converting an old milling machine (Optimum F40E) machine to be driven with a VFD, and I have it working. The head is a geared head, and with correct settings (torque compensation) in the VFD I can overcome the startup torque in the gear-train when the machine is shifted into the "high speed" gear.

There is continuity between all six terminals in the terminal box on the motor.

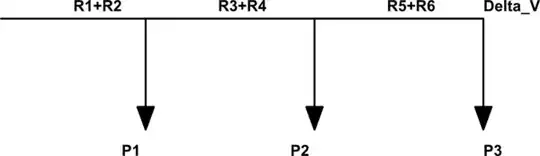

I measured the resistance between U/V/W 1..6 and found something unexpected. The housing for the wiring doesn't contain any bus-bars, so the motor must be internally wound a specific way.

Here's the motor info plate:

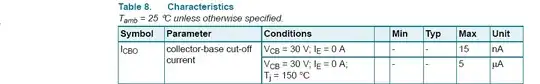

The resistance between the terminals is as such (I measured every terminal combination explicitly, even though this is redundant)

Is this a star, or delta internal configuration, or is the motor damaged?