I have a delicate problem which I'm not sure how to solve properly due to my limited electronics education: I have an old computer system from the 90s which contains an additional module replacing its CPU. This module however does one additional thing: replace the clock source of the original system. So instead of the computer's 32 MHz it generates 50 MHz of its own. This new clock goes not only to the new CPU (on the module) but it is also distributed to a couple of places on the computer's PCB.

The computer system's PCB wasn't state of the art of its time when it comes to proper signal routing, so it's more like luck than proper engineering that the signals don't influence each other. This is especially true for the original 32 MHz clock which is forked into three separate paths (CPU, FPU and an additional custom IC; this is a simplification but it should give you an idea).

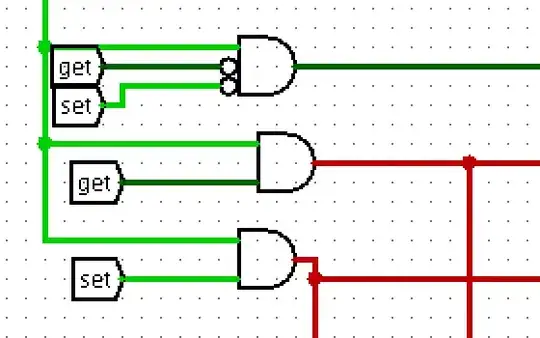

And this is where it gets interesting. When this new module was installed, part of the installation was to physically cut/scratch those three clock paths on the PCB and feed the ICs from the new clock using, yes you've guessed it, simple wires:

The idea was to mitigate the problem with unreliability of the old traces and shorten the path between clock source and destination. The original installation manual emphasises making the wires as short as possible and as straight/parallel to each other as possible, avoiding crossing other ICs on the PCB and so on; it's clear that the authors were aware of fragility of their upgrade.

This worked fairly well for... some installations. As I have discovered, mine suffers from slight interferences and from my experiments I could tell that it gets better or worse depending on the wire, its position, nearby wires etc. As I can't change the computer system, I'm stuck with trying to come up with some kind of workaround.

So this brings me to my question: is there a way to make those patch wires more resistant against environment (and each other) ? I've studied quite a bit about Faraday cages, EMI, shielded cables installation but none of the articles / videos gave me an idea how to solve my problem. Usually they would discuss connecting shielded cables into the cage like this one: Solid Faraday cage with a hole for a wire but what if I don't have a cage to connect to? Basically both ends are open (one is a typical ribbon cable connector, the other is soldering directly on/near the IC's clock pin).

Many articles state that shielding itself doesn't have any protective features unless connected somewhere (usually the cage's conductive interior) and this is where I've started scratching my head. These days one can purchase the nice thin shielded SMA cables but what to actually do with their shielding?

The best I could come up with was to create a small cage around the ribbon connector (on the module), mount the SMA connectors on it and let the other end, well, as is. But maybe this is total rubbish with no additional benefit (maybe even making things worse?)

As I said, this really isn't my cup of tea to handle so I welcome any hints to make this setup more reliable.