I recently purchased a few single phase 230V motorised hoists and I want to understand their wiring and how they work. I can more or less follow what's going on, I just don't fully understand why certain things are being done.

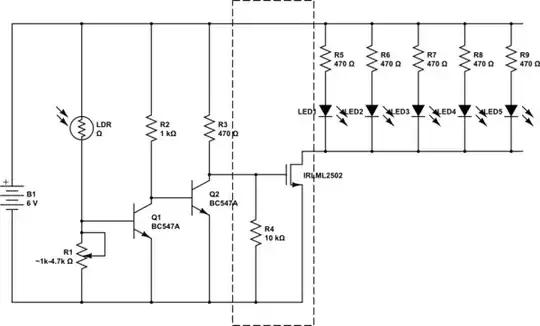

- What are the capacitors for and why are they different sizes?

- How does this motor change direction?

I was of the understanding that to reverse a motor you had to flip the polarity of one of its windings. I also initially thought that one capacitor would be for starting (with a centrifugal switch to stop it) and one for running but after looking at this diagram, that is obviously not the case.

If possible, I'd like to eventually wire them to one controller but the fact that the capacitor is in the controller makes me unsure if this would be possible. Can this be done or would more than one motor overload a single capacitor?

Combining multiple controllers into one. More detailed question: Combining multiple motor controllers into one.