There's another way to do it that doesn't use simple slip rings.

Instead, you induce a current in a coil by moving it through a magnetic field. If the magnet is stationary, and the coil is moving with the shaft then current will flow.

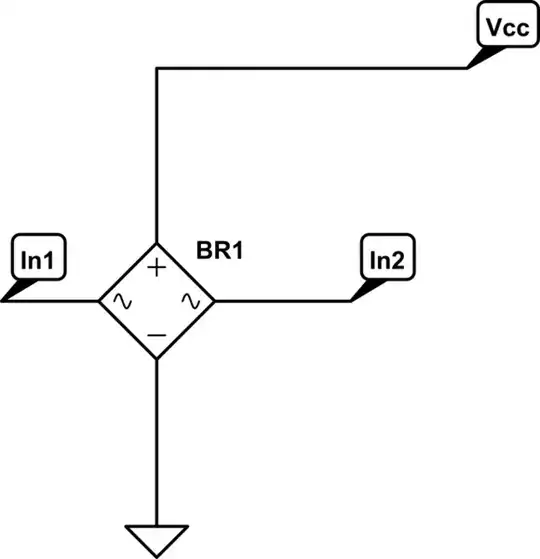

Downsides are that the current will be AC as each side of the coil passes through the magnet. So you put a rectifier on the moving assembly.

You probably need a series of coils in a circle, and a series of magnets which could be permanent or electromagnets.

Also this will provide resistance to rotation so you may need more motor power to turn the shaft.

Finally, this won't send power unless the assembly is rotating. If you stop it spinning, then no power will be transferred across.

And you can't earth via an inductive pickup. This makes the rotating assembly isolated unless it earths through bearings, which might be okay depending on load. Bearings don't have a lot of contact area for current.

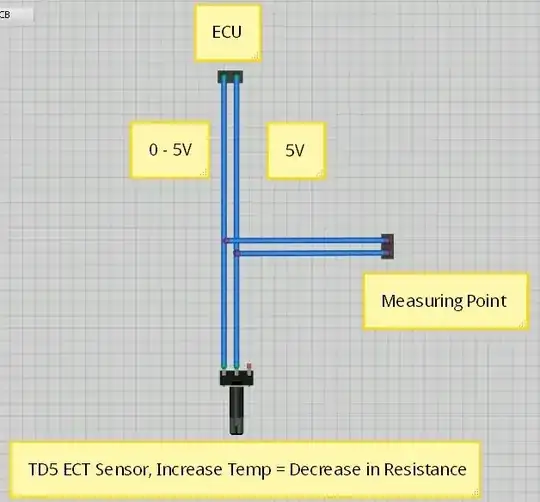

For completeness only - DATA

If you wanted to send a digital signal across the rotating interface, then a series of optocouplers could do the task at a fairly low bit rate.

For higher speed connections, perhaps fit a wireless ethernet card to the rotating assembly and use radio to jump the gap. A Pi on a Maypole might be perfect.