I have a car HVAC daughter board that set a pin to a specific voltage depending on which of the 6 physical buttons is pushed. I don't have any schematics neither datasheet. I measured voltage of this pin when each button is pushed. I have then 6 values.

I would like to turn on one LED only when my input is between a given range (for better accuracy even then I measured a specific voltage for each button). So I have my 5 V rail, and an input that I want to use to drive 6 LEDs.

I want this input to light on :

LED1 only when 3.08V > input > 2.88V

LED2 only when 2.76V > input > 2.56V

LED3 only when 2.34V > input > 2.14V

LED4 only when 1.75V > input > 1.55V

LED5 only when 1.01V > input > 0.81V

LED6 only when input < 0.5

Basically, I want to make something fancy, light up one led at time for a specific button pushed on a daughter board.

I read those two topics that gave me hints:

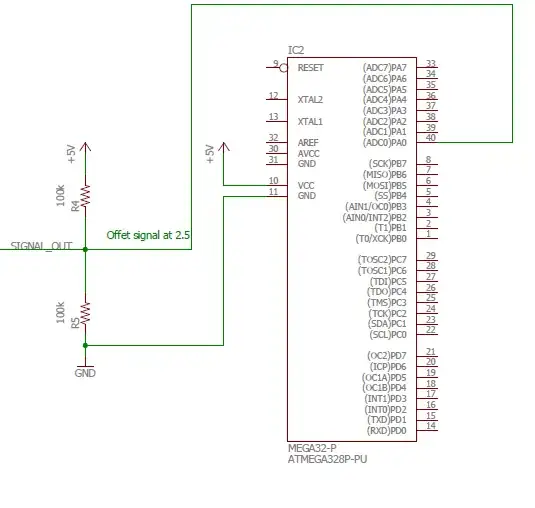

I understood that I will probably have to use window comparators like the LM339B but I have no idea how.

Would you please explain the simplest way to achieve this? If you can provide a schematic, I would appreciate it.