I am designing a device based on TO-247 MOSFETs. The power is pretty high - about 50W per package, so it's going to be either water-cooling or something big with fins and fan. All is great, except they have the drain connected to the thermal pad.

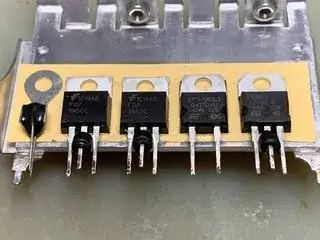

So common heatsink should somehow isolate between the different drains.

One way is by the thermal pad, but since I am using relatively high voltage (400V) it scares me that a thin pad may be punctured.

But I am out of good ideas about what else it can be.