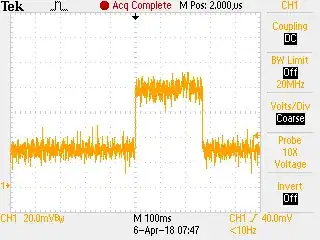

why would the output drift in such a predictable, repeatable, and

reversible way?

This sounds like a high-resistance short between Vdd and GND - one of the type that might be introduced by very slow water incursion.

The sensor's voltage output is referenced to Vdd, and the operating range of Vdd is 1.8-3.6V; if you normally supply it with 3.3V, fluid incursion could cause Vdd to drift down as the high-resistance short between Vdd and GND slowly decreases in resistance, and the outputs will drift down with it. It's likely the sensor would completely shut off given more time under these conditions, once Vdd drops below 1.8V.

This would also explain why the fault takes a while to manifest, but manifests more quickly once it's occurred once. Water may have saturated something, or left salt deposits which get quickly re-dissolved by future water.

The datasheet has this to say about waterproofing:

In products like outdoor watches the electronics must be protected

against direct water or humidity. For those products the MS5803-02BA

provides the possibility to seal with an O-ring. The protective cap of

the MS5803-02BA is made of special anticorrosive stainless steel with

a polished surface. In addition to this the MS5803-02BA is filled with

silicone gel covering the sensor and the bonding wires. The O-ring (or

O-rings) shall be placed at the outer diameter of the metal cap. This

method avoids mechanical stress because the sensor can move in

vertical direction.

Are you following their design guide here - provide your own robust waterproofing for the PCB side of the sensor, use an appropriately-rated O-ring to seal the housing exit, and only let the metal cap contact water? Water could be getting in through the silicone inside the sensor's metal cylinder, but it could more simply just be getting in through your own waterproofing around the sensor.

If your waterproofing is perfect, you still might be slightly out of spec, as the datasheet does not seem to indicate any rating for sustained immersion. But if you have an example of the part being used successfully in this manner (dive watches), it may still work. That said, do these dive watches actually expose the metal cap to water, or do they use a rubber membrane to transmit pressure to the sensor without immersing it? If the latter, you're probably out of luck for trying to immerse this sensor.