On the PCB I'm designing, the total power consumption might be as high as 86W (including output power), with supply voltage between 18 and 75V DC (it is OK not to allow full output power bellow 22V). So I'm fine with 4A max input current.

I'm trying to find how to do the input "fuse". I would like some non destructive over-current protection, as opening the system to change a fuse would void calibration (calibration is expensive, and can't be done in the field).

I was initially thinking about using PTC fuses, but I couldn't find any the both allowed 4A continuous current, and resisted to more than 75V. The nearest thing I found was 0ZRM0375FF1A, which is max 3.75A and max 72V (and is far to big : 34mm high!)

So what kind of component/circuit might enable to get an over current protection :

- that is non destructive (ie operational after power-off, or after some time, or ... : anything as long as it don't require opening the device)

- can withstand 4A DC continuously, and block or limit if current exceeds this current (I don't have any hard requirements there, it can be fuse like with an It², or current based, ...)

- can withstand 75V nominal (so at least 100V would be nice)

- reasonably small PCB area (in particular height <15mm)

- if possible low power dissipation when not triggered (1W max, ideally <100mW)

Do you know of any technology that might work? Or maybe there is some active solution based on current sensing+MOSFET?

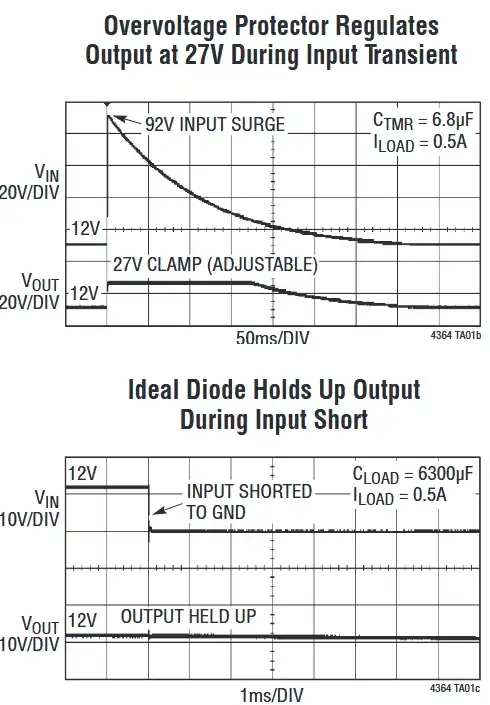

In the later case, it might help that there is already some reverse current protection in place (ideal diode): So the "fuse" might be placed after the ideal diode if avoiding the risk of reverse current makes it easier, or before if it is possible (or it might be somehow combine with the ideal diode (which does reverse current protection and current Oring)

So the "fuse" might be placed after the ideal diode if avoiding the risk of reverse current makes it easier, or before if it is possible (or it might be somehow combine with the ideal diode (which does reverse current protection and current Oring)

EDIT : Answers to the various comments : First off all, the board will be the first version of a prototype, so specifications are not well defined yet : only high level specifications are set yet, for the rest it's mainly "do as good as you can", with the particularity that cost isn't very important (if you have a 50$ solution, it's still fine), while PCB space and heat dissipation are far more important.

@TimWilliams Source can be anything (it's up to the client to provide it). Strict minimum is a 24DC (with some margin). As the secondary source is PoE, which is up to 57V, we used 18-75V converters, so it is a nice plus to have everything working from 18 to 75V (a good solution with slightly lower voltage limit is still acceptable). The Load is composed of 2 DC/DC converters, and some connection for user-specific load.

For transients, I have to admit that I don't really know what to protect for exactly : there aren't any low level requirements, it's just "protect as well as you reasonably can", while keeping PCB size and power as low as possible . I added a SMF60A_R1_00001 for some transient voltage protection. But if you have any improvements to suggest, I'm interested.

Any current above 4.5A for more than "startup" is definitively a fault. Cutting at 4A is also fine (the 18V supply + max consumption is really an edge case, so I don't care if we derate the system a bit bellow 22V)

For how fast to react, again, I don't have any specific requirements. Slow enough that it isn't triggered during power up (or faster, but limiting current instead of cutting it), and "as fast as possible" otherwise. As it is the first prototype, I'd rather have it cutting a bit too slow than a bit too fast, so at least I will be able to measure startup current to design it better for next iteration.

I don't really care about the voltage drop in itself as long as it don't exceed 1V (even 4V might be acceptable), but we are having quite a hard time managing thermal dissipation (waterproof enclosure), so I would like to keep power "loss" as low as possible (1W is really the max, it would be nice to be bellow 0.1W).

Calibration matters because there is a camera in the system which needs high quality precision, that is likely to be invalidated if opening the system. Calibrating again is a complicated process.

Generating some noise is OK (the signal will just power some DC/DCs), but I don't think a buck converter can be withing the 1W dissipation limit (it would require 98.8% efficiency)

@vir : overvoltage protection was a type (I corrected it). As mentionned, I added a TVS to help a bit against overvoltage transients. If you have any suggestions to do better, I'm interested (if it is for continuous overvoltage protection, it would only make sense if resisting 320V DC or 230VDC, but those cases are quite unlikely, so I wan't planing to protect against them : but if you have a compact solution, why not).

For fuses/breakers outside the enclosure, it's sadly not an option, as the device has to be waterproof