I'm a PCB rookie and just got the first sample of a 4 layer flex-rigid board that I made.

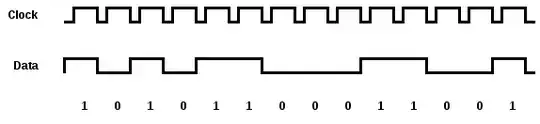

I'm using 3.3V TTL-UART @ 115200 baud, the stackup is as follows:

- CU 35 (signal)

- Prepreg 0.7mm

- CU 35µm (GND)

- Core (Polyamid) 25µm – 50 µm

- CU 35µm (power)

- Prepreg 0.7mm

- CU 35µm (signal)

I previously made a schematically more or less identical rigid-only board that works fine, but now that I added a panel connected by a flex cable my serial lines look worse. Instead of a square data wave, I see a triangle wave. I'm focusing so much on the PCB since the first board is fine, the second one is not and the only significant difference is the stackup.

Unfortunately, I can't share pics from the scope because I broke the board, but I did not get the typical curves I'd expect from capacitance where the derivative decreases close to the high side on the rising edge and close to the low on the falling edge. It looked more like a proper triangle wave.

What could be a probable cause? What could be an easy fix for the next revision?

I'm thinking that the thinner flex core between my inner layers creates capacitance that interferes with my data line. But I'm not sure... Any tips?

I was thinking I should use an LRC meter to measure the capacitance on the trace on a naked pcb. Does that make sense? I'd measure from the processor pin and a nearby GND?

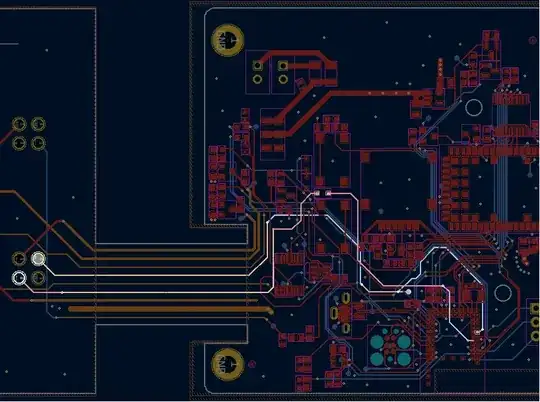

New board, Rx & Tx highlighted (the left hand part only contains connectors, the right hand side is more or less the same as the old board):

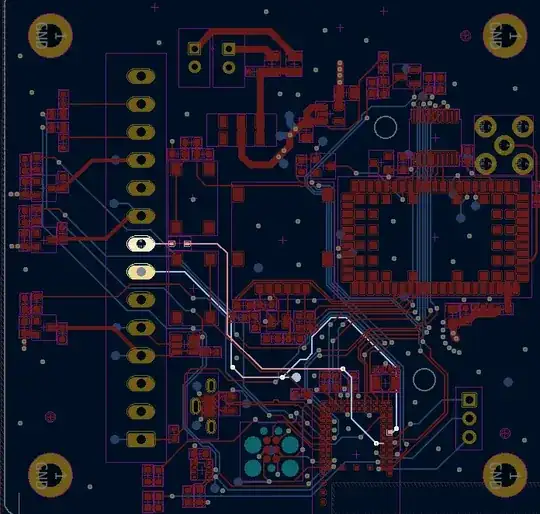

Old board, working fine. Nice waveforms.