Power resistors aren't going away, at least not any time soon. There are many places where you just can't return some power but must dissipate it in situ instead.

A dramatic example is braking resistors: on a diesel-electric train for example, the engine can only generate power (there is no currently known reaction process to reverse fuel combustion, at least not in anything resembling an engine!), so the generator is no good to absorb the excess power that is available say while descending a hill, or when slowing down. However, if we simply toss a big fat resistor on the traction motor (or rather its controller), we gain the benefit of a wider-range and continuous control method (we can vary torque from positive (driving) to negative (braking)) while extending the longevity of the [mechanical] brakes on the train cars. That is, suppose you had a car that, instead of two pedals (throttle and brake), you had one lever that moved smoothly from "go" to "stop" (or to "reverse", even).

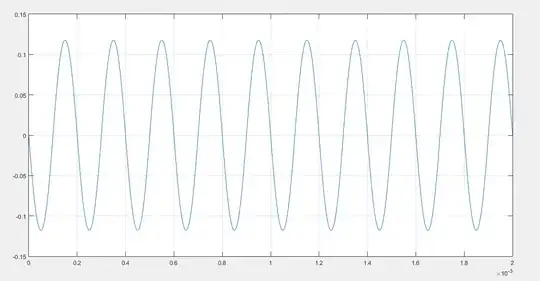

Another example is when it must be done very quickly. Snubbers are a typical application, where some unintended LC circuit elements become excited, say in a switching power supply. That excitation leads to increased peak voltage or current at the switch, and often increased EM emissions too. These can oscillate in the 10s of nanoseconds, just not enough time (among other constraints) to be able to transfer that energy somewhere useful. In that case, it's more effective to simply dissipate the energy as heat.

There are some ways around this -- SMPS can be built with topologies that recirculate more of this leftover energy, or indeed even harness it. But they come with some limitations of their own, too (e.g. the flyback topology places harder demands on its filter capacitors). Also, even more mundane: the cost of recirculating circuitry might simply not be warranted for a given product. It's all economics in the end!

Most generally, we have applications where we simply have a voltage or current, and want the other: resistors are used for current limiting (I = V/R), current sensing (V = IR), and measurement (R = V/I). Current sense (shunt) resistors can be made in quite small values (I have a few 100µΩ parts in stock, myself), but as currents go up and up, they can still end up dissipating quite a lot of power. And you can only reduce the sense voltage so far, before too many errors creep in -- even using good layout and a precision amplifier.

Losses can easily be improved, in some easy cases; when the sensed current is AC, it can be coupled through a transformer, and then a proportionally smaller "burden" resistor is needed. A transformer cannot convert current to voltage by itself, though: the resistor is always needed. (Well, you could use a transresistance amplifier to do the conversion instead, but that's most likely still constructed with a resistor!)

Similarly, resistor voltage dividers can be made with larger values, as long as this is suitable for the application. An oscilloscope probe could be made with 450Ω series into a terminated 50Ω cable (a "low Z" probe), but this draws quite a lot of power for many small-signal and DC biased applications. A probe might instead be made with 9M into 1M, where the 9M has some capacitance across it to compensate for the capacitance of the cable and scope input. The 10MΩ total draws very little power within ratings, so makes a good probe (as such).

As for the form of said resistors -- there are 1W SMTs too. A typical 2512 [imperial] chip size resistor is good for 0.5W or more. You need to dedicate quite a bit of board area to achieve this, though: the chip is heatsunk through its pads, so you preferably attach large copper pads on the PCB to it. If you're constrained on space... it might simply be better to stand that resistor up vertically.

THT resistors can also run much hotter. Constructed from ceramic materials, parts are available with temperature ratings that would literally desolder themselves -- if the hot part weren't kept responsibly away from the solder joints, that is. Higher surface temperature, means more heat into the surrounding volume of air, and faster rising convection currents. I have some 0.5W metal-oxide (and silicone enamel, I think?) resistors that are the same size as conventional (carbon film / epoxy enamel) 0.25W resistors, for instance. To avoid desoldering (not to mention PCB charring, etc.), it's a good plan to stand these resistors up off the board, perhaps using ceramic spacers, or by clinching the leads to stay up off the board during soldering.

Power resistors can also handle higher voltages. A typical 1W THT resistor is rated 300 or 400V, and HV types are available up to a couple kV. (A nontypical 10W HV resistor might be rated 10kV or more; but it will be much longer to avoid arcing along the body length itself, and the power rating is just kind of a formality at the megohms many such resistors have.)

Mind, it is usually worthwhile to sense modestly high voltages with SMTs. It's a common sight in off-line SMPS to have a chain of three or more 0805 chips in series, say across-the-line (to discharge the line filter capacitor), or to sense supply voltage (dividing it down to a comfortable say ~5V range that the controller IC is comfortable with).