I am trying to design a compact robotic actuator. My main focus with this project is to reduce the amount of external wiring needed to do with robots. With that in mind, I have thought of the following high-level overview for my robot:

I found that using the CAN protocol to communicate between each of the Joint controllers would make sense, since the CAN protocol can be daisy-chained. I would like to use something simpler like an I2C/SPI since I have zero experience with the CAN bus.

My first question would be: If I want to daisy-chain my actuators like this, can I still use SPI/I2C? Since SPI takes a SS pin per node, I am worried that I would not be able to do so. I would really like to use I2C, since it is a very simple protocol.

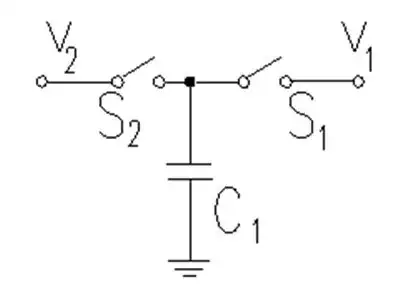

If we now come take a look at what happens inside each joint controller as follows:

Here I have imagined that I would have no other way but to use CAN, however I would like to use I2C if possible.

My second question to you guys would be: Is this diagram valid? Can I start designing a schematic around this block diagram?

My final question would be to know how it is done in the industry - especially the cable management. I could not figure out a way to have no wires coming out at all, yet the robots I work with all have their wiring managed internally.