In order to ease supply issues, I am considering an overlapping footprint for the TQFP-32 and VQFN-32 packages of ATmega48/88/168/328 CPUs. The two packages have the same pinout. It's a commercial project, likely to make a few thousand units over a five-year period.

Has anyone tried this successfully? Are there any surprises? Any issue because of the signals going a little under the (larger) part? Any issues in fabrication or placement?

Obviously the alternative is to have to have multiple-version PCBs, with the additional documentation management overhead. This way obviously "wastes" the area under the chip for tracks.

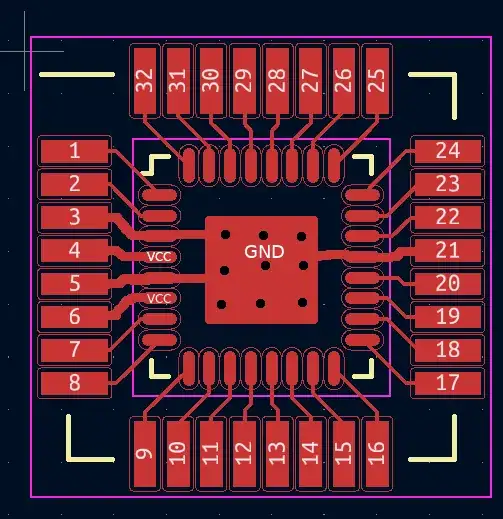

It would look something like this (updated with thermals and GND/VCC):

Additional information in response to comments:

- The design uses the internal oscillator

- There are no analogue inputs or outputs

- Most of the outputs are PWM; also RS485 at 250 or 500 kbit/sec; some i2c.

- Bottom thermal pad will be connected to GND, with thermal vias, per datasheet p643. Pins 3, 5, 21 are also GND; pins 4 and 6 are VCC. The smaller part has a thermal pad on the bottom, the larger one does not.