I have been given a small portable vacuum cleaner with a faulty battery. The battery is an 18 V, 5-cell 21700 unit with a large BMS board on top. One cell wasn't reporting voltage so I replaced it with a brand new cell of the same spec (Samsung INR2700).

When placed back in its original charger it is still detected as faulty. Is there anything else I need to do to reset this battery so that it will charge once more?

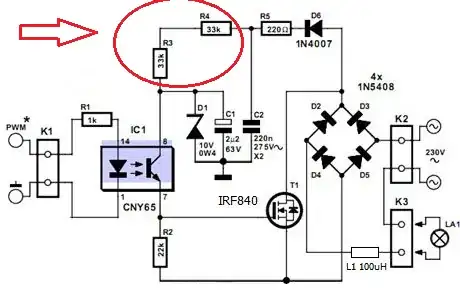

I have found a 3.3 V header on the BMS with pins SWCLK/SWD0/GND/3.3 V/RESET pictured below. Do I just need to bridge the reset to ground?

Further investigation reveals a labelled UART 3 pin header which I will try hooking up.

Just hooked up the 3 pin serial. 115200/8/n/1 left to right GND-TX-RX and I get output via gtkterm as follows:

main - line: 00051: mcu reset...

nvram_if - line: 00172: calbriated_flag = 1

nvram_if - line: 00269: sys_record,fault:0x80,inc_soc:88739

nvram_if - line: 00330: bms_mode:87654321,bms_mode_size:4

state_poweron - line: 00025: state_initialising_entry.

state_poweron - line: 00059: permanent defect exist :0x80.

main - line: 00077: compile time: Dec 14 2018, 09:15:26

main - line: 00079: software version: 01.16.0001.2018.12,13

main - line: 00083: PCBA_PN:280796003

main - line: 00085: sizeof test: sys_defect_t=2,cell_new_old_t=1maistate_poweron - line: 00085: state_initialising_exit.

state_defective - line: 00033: state_deftaskey pressed,stmach state:4

task_led - line: 00423: update led style:5

task_debug - line: 00032: calibration flag : 1

task_debug - line: 00034: defect: 0080

task_debug - line: 00036: sys state: 4

task_debug - line: 00038: led.style: 5

task_debug - line: 00040: nv_life:88739

task_debug - line: 00042: bms_soc:0

task_led - line: 00423: update led style:0

state_defective - line: 00076: state_defective_exit.

state_poweroff - line: 00025: state_power_down_entry.

system_timing - line: 00093: task delay warning,id:1

state_poweroff - line: 00049: pwr_off_#1.

task_debug - line: 00047: cells volt(mV): 0, 0, 0, 0, 0

task_debug - line: 00051: cell sum(mV): 0

task_debug - line: 00053: pack volt shunt(mV): 0

task_debug - line: 00055: pack volt(mV): 65535

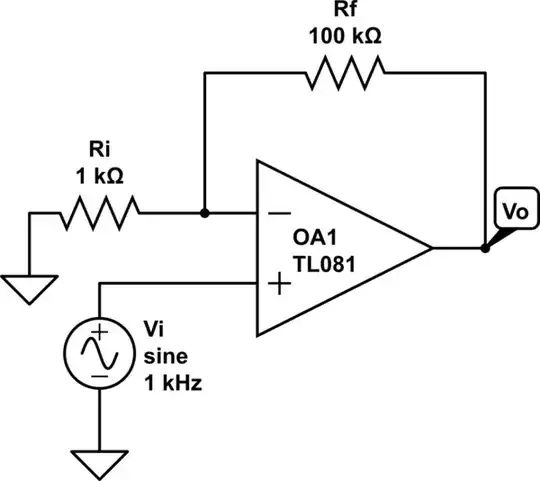

added closeup of main IC