I would like to use a pull switch as a trigger for an alarm that I'm building. When the switch is triggered it will turn on a siren and potentially a strobe light. I've found plenty of options out there, but the prices are a bit staggering.

Take this one for example, it's $238. I was thinking $20 would be expensive! My alarm isn't going to be used in an industrial environment and the items I'm securing aren't worth enough to justify spending that kind of money for a switch.

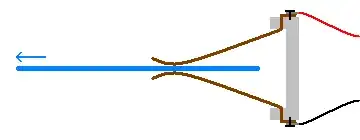

I think a simple pull type light switch would be sufficient, but I need the cable to break away from the switch when activated and not damage it in the process.

I guess I have two questions:

- Why is this switch so expensive?

- What other options are there for a N.O. pull cable switch that stays closed after being activated? I'm open to ideas of building my own switch.