I'm working on a design that requires a clock generator with variable pulse width. The pulse width is controlled by a potentiometer, and the clock speed is controlled by another potentiometer. It's supposed to work by using a 555 timer to generate a up-ramp wave, and then by comparing it to an offset created by the pulse width pot turn it into a variable width pulse wave.

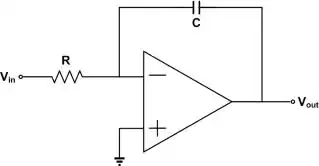

Can anyone see any issues with this? The 555 up-ramp design is based on this article.