Story

Get my hands on two Metabo (made in Germany) cordless DC battery powered hand drills previously thrown away because of..... the batteries, how sad. The overall construction is simple however pretty stiff and clever designed with quality components.... a keeper! "The Post Apocalyptic Inventor" aka TPAI made a video about making obsolete tools useful again. The solution is simple, use an external battery or PSU to power the tool by installing a connector. I did it a little different, used a different and more regular connector and install the connector on a different location. The result is actually equal to the TPAI version.

Problem

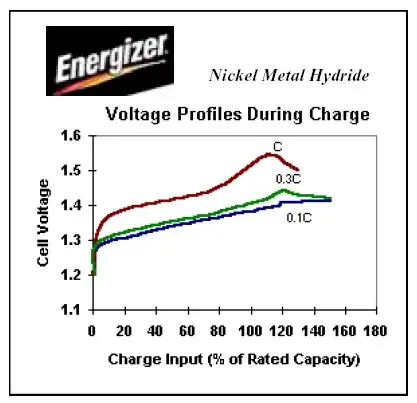

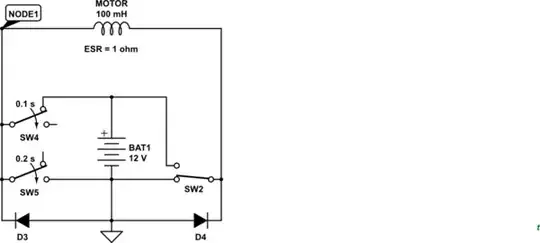

At the first try, I notice that after starting the motor (huge inrush current anyway) it stops immediately (with some reverse turn shake feedback). Through the ventholes of the motor I noticed some huge sparks when the motor stops. This abrupt "kick out" behaviour is not very healthy for the switches, bearings, the gears and the brushes, possibly effecting the lifetime of the device. I have notice similar behaviour at other brands, only at high speeds and release the (speed controlled) trigger quickly. These ones has no electronic speed control, it is just on or off in selected direction.

When disconnect the power source (remove it), this problem does not occur and the motor slows down by friction and power loss.

After figuring out how it works (very clever designed in matter of simplicity of construction) I understand why.

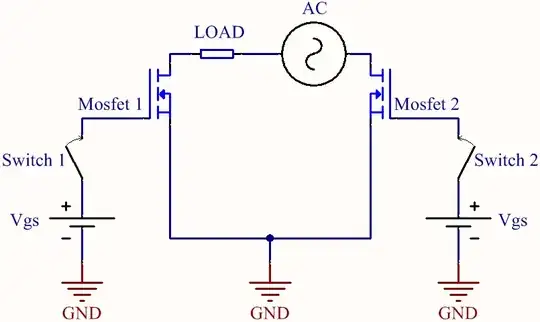

The motor is shorted (in feedback/generator state) when releasing the power trigger, because of the clever configuration of the two 2-state power on slash direction switches in parallel. However this results in a huge feedback current and build up coil voltage inside the motor. That is the reason why the brushes spark intens and the motor stops immediately after high speed rotations. To avoid feedback to the batteries this is good but can have some negative impact on other components because of the sparks and internal feedback force.

Question

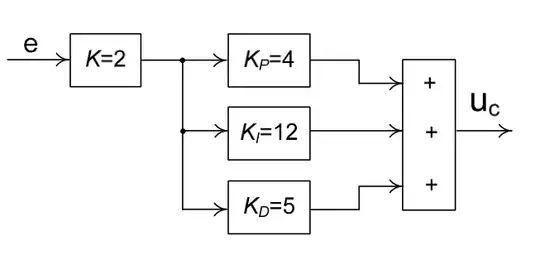

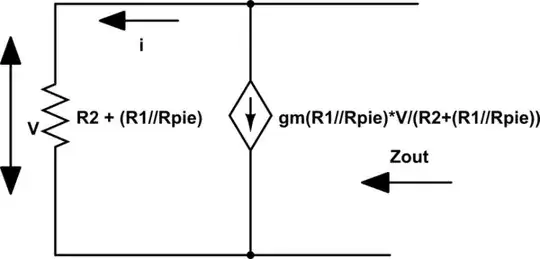

- I have tried to design a new addon solution (mod) in the existing configuration. Cut the negative lead and added two diodes and a resistor. I am not a professional so I wonder if this is a plausible solution to slow down the decrease of speed and limit the feedback current/voltage inside the circuit. What do you think, it this okay?

- If this solution is plausible, why manufacturers do not apply this even at quality tools? To avoid the best quality? Wear is a selling point?