Yes, you'd run AC L1 and L2 to the rectifier "~" terminals and the kiln elements to "+" and "-". You do not need (or want) to connect neutral. And, do not connect the heater element to safety ground: that is unsafe!

(I'm not sure what you mean by "kiln is only pulling 100 volts". Do you mean watts? And it would be up to 12kW if it's on a 50A circuit. MORE: ok, there is an SCR chopping the AC to a bit less than 42% of full power. This could interact with the rectifier you propose, but probably will still work.)

Here's a related question about SCRs controlling heaters: How to use SCR to control the power of a heater. I suggest you study this and understand better how your controller works before you try this.

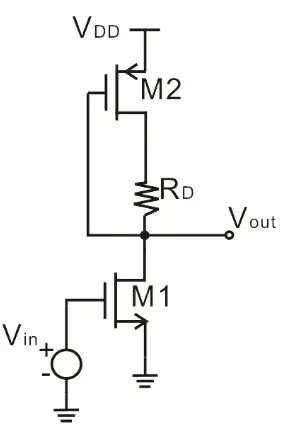

Say you wire up the rectifier. It will not be putting out smooth DC. Instead, it will be pulses at 2x the line rate, and when applied to the heater it will do practically the same thing as AC. That is, elements will emit heat that has a small 2x line-rate ripple element to it. The heating element ends will be swinging from 0 to +165V (+) and 0 to -165V (-), respectively, vs. +/-165V for both ends when using straight AC.

Here's a sim showing that (simulate it here)

Given more time we could simulate it with the SCR chop.

You could smooth the ripple by adding capacitors. Then you will be left with having a DC bias across the element. Then this can test your AC power hypothesis. I'd be leery of this however, as this will interfere with the SCR and possibly damage it.

Which brings up another hypothesis: ionization. AC or DC, the elements will have a voltage gradient across them. As stated, the ends will be swinging +/-165V with the 0V point roughly in the middle. In heated air these differences will create ionization paths, which could be influencing your melt.

A possible experiment: add a grounded screen of high-temp metal (Iconel or such like) between the elements the crucible. This would block the ionization path near the crucible.