As you might know, it is hard to get components these days. That's why we engineers have to get creative sometimes ;-)

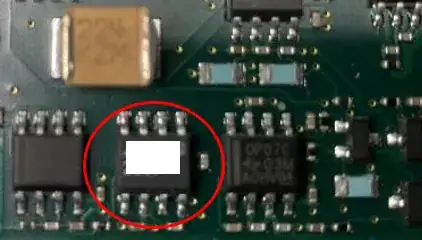

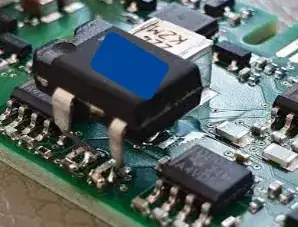

The company I'm working for has a shortage of a Zener-type voltage reference which comes in a SO8 package. We have found about 3'000 pcs. of the same voltage reference, but in a DIL8 package. The application is a precision measurement device (I'm sorry for not being able to give you more details on the PCB and the IC). We plan to use all 3k DIL8 references.

So we need to bend the DIL8 legs with a custom made tool and solder the DIL8 packages on the SO8 footprint (only 3 legs are used/connected)

Of course this looks very ugly, but an ugly look should not disqualify a technical solution, right?

We passed the following tests:

- Measurement performance (with the usual humidity and temp profiles)

- Vibration tests (X/Y/Z, shock 70g/6ms, vibration sweep 3g 10Hz-2kHz, vibration noise)

- EMC immunity

My questions:

- What are the possible failure modes of this unconventional soldering?

- Would you use additional hot glue for fixation (despite the positive vibration tests?)

Any additional thoughts and ideas are welcome. Thanks!