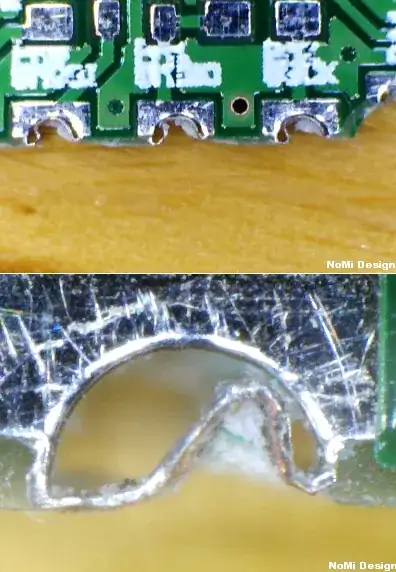

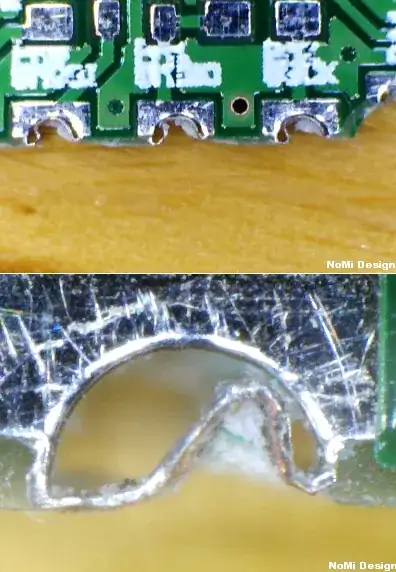

It's perfectly possible to reflow your motherboard, but you have to do it really carefully to avoid destroying it. Several things can go wrong during soldering: thermal stress caused by different parts of the board being at different temperatures, and chips getting too hot. The reflow soldering process is designed to avoid these problems. This is the temperature profile of a typical reflow soldering process:

(source: apemswitches.be)

The idea is to pre-heat the whole board to a high, but safe temperature. It is then held at this temperature for about a minute, allowing everything, even the insides of the chips to reach the same temperature. Then the temperature is briefly brought up to the melting point of the solder, and then the heater is switched off, and the board is allowed to cool slowly. Fast cooling will cause thermal stress, and can shear off solder joints, especially on large BGA chips.

This is what you should do:

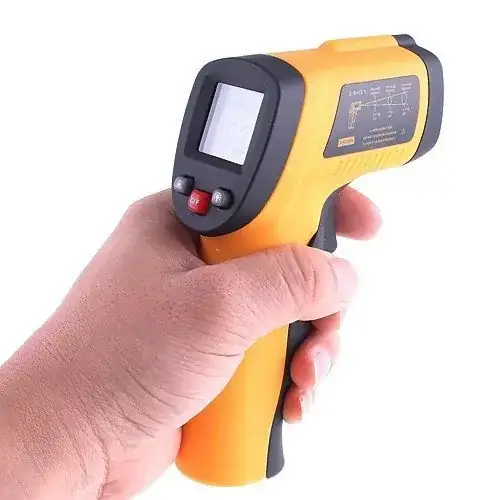

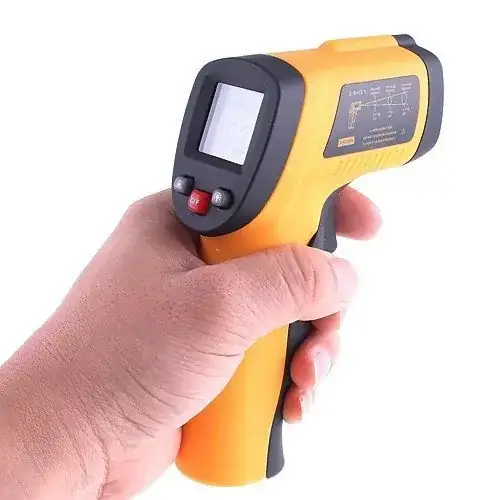

Pre-heat the board in an oven. Try to raise the temperature fairly slowly, taking about three minutes. Get a laser temperature probe, and check that the board is about 180ºC all over.

Now get your heat gun, and heat up the suspect component, taking care to heat it evenly all over. Keep the temperature sensor pointed at it the whole time, and stop heating when you see the temperature hit 245ºC, or when you see the solder melt all over.

Put the board back in the oven, and switch it off. Allow it to cool gradually, and take it out when it's safe to handle, about 40ºC.

Your processor can operate reliably upto 80º or so. Above this it will not operate reliable, but won't suffer permanent damage. Above the reflow temperature may cause permanent damage.