I am redesigning my boat's DC electric circuit, and when looking at the main battery fuse to determine its correct interrupt rating (i.e. the current the fuse will be able to fully interrupt without arcing or exploding, not the current at which it will start melting), I started wondering about the interrupt rating of all fuses in the circuit powered by said battery.

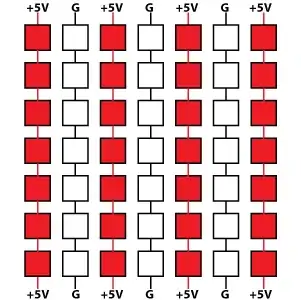

Indeed, consider the schematic below, assuming that each fuse is sized according to the cable it protects on each branch.

Let's imagine that the battery has very low internal resistance (LiFePO4 bank), that the battery fuse is a beefy 800A class T fuse (DC interrupt rating of 100kA), and that F1, F2 and F3 are 10A automotive blade fuses (interrupt rating 1000A).

Let's look at what happens if there is a short to ground on branch 3, pretty close to the distribution panel (the resistance of the short-circuit will be the lowest):

We all expect that F3 will blow. However, given its interrupt rating of 1kA, there are good chances that an arc may form, and that that F3, S3, the wire and part of the distribution panel will explode / melt / burn / make a big mess, before F0 has any chance to blow (it will take a few second with 1kA in a 800A class T fuse). Note that the cable from the battery terminal to the distribution panel will be pretty beefy so it won't melt and will have very low resistance. All the energy will dissipate downstream of F3.

To me, the only way to be 100% sure that such a scenario cannot happen (and as we are talking of a boat I really don't want it to happen at all) is to only use fuses, wherever they are in the circuit, that have an interrupt rating equal or above the estimated short circuit current of the source which, if it is a sizeable LiFePO4 bank, can be tremendous. Also, I am not too keen to rely on F0 to blow any time there is a short in the circuit to ensure its safety. Large class T fuses are pretty expensive!

Is this a correct assumption and, if not, why not?

What makes me wonder is that I have never seen this recommendation anywhere, and automotive blade fuses are commonly used on boats / RVs distribution panels despite their relatively low interrupt rating (much lower even than what even a relatively small AGM battery bank can send in a short circuit), downstream of a master battery fuse that would take less time to blow than necessary for the fused branch's cables and devices to explode.

Is there a good reason for this - that I may have missed - or is it just that nobody really realises what could happen in a short circuit protected by a fuse with an inadequate interrupt rating?

EDIT 23/06/2022:

In some of the answers, there are suggestions to increase the voltage as the currents are too big. While very reasonable suggestions, they do not really answer the question, and I believe my question still applies for more conventional installations.

The 800A fuse rating quoted above was voluntarily quite extreme (and higher that what I would see in my own install) to further highlight the issue.

A reasonable LFP bank or even a few large AGM batteries in parallel, which is a relatively common setup on boats or RVs with an inverter (yes, there are very valid reasons to use a 12V DC inverter), can easily create currents of dozens of kA if it is shorted. If the main fuse is 300 or 400A class T it will be faster to open at 1000A but may still take enough time for damage to be caused downstream on the fault branch.