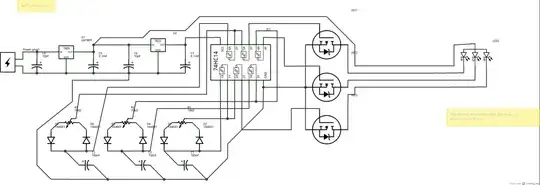

I am currently working on this design and I would like to see if I can get some feedback regarding the protection for my MOSFETs and see how I can introduce dead time as I would like to prevent any sort of inductive spike or stalling my DC brushed motor. The four MOSFETs I am using are the IXFB210N30P3.

- 32,302

- 33

- 134

- 249

- 21

- 2

-

1The easiest way is to use a dedicated H Bridge motor control IC that would have such protections built in. – Kyle B Jun 03 '22 at 21:42

-

How do you create the drive signals CLW and CLC? For dedicated dead time generation via microcontroller you need 4 separate signals. The circuit suggests, that you have only 2 signals used for both sides in common. This limits the dead time control to hardware, gate resistors and the fixed 25ns of the IR2110. – Jens Jun 03 '22 at 23:10

-

I will be introducing dead time through an arduino, but I am unsure on how to model dead time on LT-Spice. – Mr. Capacitor Jun 04 '22 at 03:29

-

See here for a method of generating deadtime that you can use in a simulator: https://electronics.stackexchange.com/questions/517113/driving-low-voltage-p-mos-n-mos-half-bridge-with-dead-time-control-without-boot – John D Jun 04 '22 at 17:58

2 Answers

Your FETs have body diodes, and you've also added external diodes so inductive spikes shouldn't be an issue. Any extra inductive energy will be clamped to a diode drop above the supply voltage.

However, your motor and load may have a lot of rotational energy, and when slowing or reversing direction that energy goes back into the input supply. If the input capacitors can't absorb it before the voltage rises too much, you can destroy your FETs and even your capacitors.

Solutions to that are to add enough capacitance to absorb the expected energy, or to use a comparator to switch on a dissipative (resistive) load on the supply when the voltage rises to some safe setpoint.

You can also limit the rate of braking and reversal so as not to pump the supply up to an unsafe level, but having an additional backup is safer.

As for dead time, the IR2110 doesn't have explicit dead time added internally, so you're responsible for adding the appropriate dead time in your drive scheme, which you don't give any information about. There are discrete dead time circuits you can build with a few gates that you could use, or if whatever your controller is supports it you could do it there.

- 22,677

- 1

- 39

- 56

-

Thanks, currently I am utilizing a mean well power supply rated at 120V and 25A. With a previous circuit, I burnt many power MOSFETS and I am just trying to take as many precautions as possible. My dc brushed motor has a peak stall current rating of 65A, however, I have observed that when the circuit goes bad the power supply automatically begin bipping and shuts itself down. – Mr. Capacitor Jun 03 '22 at 21:53

-

What are you doing when the problem happens? Does it happen at start-up, or when the motor is slowing/reversing? Could be shoot-through or bus overvoltage. – John D Jun 03 '22 at 22:15

-

usually when that happens I disconnect the power supply. Every time that has happened we end up with shorted out MOSFETS. I have ran into this issue when I try to switch to another direction or when i let the motor run in 1 direction for a couple minutes it'll just stop and MOSFETS blow smoke. – Mr. Capacitor Jun 04 '22 at 03:28

-

I think you'll have to do a little more troubleshooting to find the problem. Can you instrument the gates to measure your deadtime? Also monitor your bus voltage to see if it's going too high. Finally, we don't know anything about your thermal design, so if your FETs don't have adequate heatsinking you could also get into trouble. Maybe start out safe by using a lower bus voltage while troubleshooting – John D Jun 04 '22 at 17:56

-

Thank you john, i will test and check my circuit with a bench power supply before hooking it up on the actual 120V supply. I am seeking more resources on dead time as i am having a hard time wrapping my head around it. – Mr. Capacitor Jun 06 '22 at 00:09

You must examine the L/R =T time constant for each of the diode and resistor response times.

A brake load dump resistor is best for removing rotational energy rather than PWM heating up the motor DCR losses. Butyou must control the rate of current and thus acceleration/braking with suitable switches in the 1 mohm range using a Dual Nch half-bridge or ESC rated for much higher currents and Pd heatsink.

You must also examine stored energy and power*t vs the load resistance and thus load power and Q amplification ratios as a function of time relationships that affect overshoot and deadtime impulses.

Very low ESR to L load leads to resonance with Parasitic V to high Q errors. But high series R dampens response with low efficiency.

Your load of x mH does not include DCR, which is essential as well as SRF from parasitic C vs switching f.

The gate drive asymmetry T for turn on vs off determine with load Ciss the deadtime.

Your gate drive has a Schottky power diode of resistance due to Ciss currents and Gate resistance current limiting in the xx mOhm range in shunt or parallel with 5 ohms which is compared with Ciss and Rg gate load and may be excessive dead time. Thus excessive spike duration and EMI from rise time and energy radiated at high impedance during "deadtime".

Let's review these parameters and consider how to prevent cross conduction faults vs high spike EMI issues. You may need to explicity model these parameters and need to reduce the Zon/off ratios to reduce Tdeadtime and V=Ldi/dt voltage spikes a better way without compromising and even improving efficiency and EMI.

- 1

- 3

- 54

- 182