This is for a 24V 6.25A power supply. The power supply brick will feed into the connector then power a prototype device.

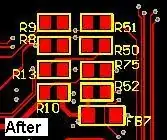

What are the conventions or best practices to solder a wire to a much smaller diameter connector, as pictured here? The (outer) diameter of the gold connector is 1.54mm (~14 AWG) and the diameter of the unjacketed portion of the wire is 1.9mm (~10 AWG).

Intuition suggests I will have to solder as I normally would and try to be as neat as possible, using heat shrink at the outset.

I am also thinking of a product and a quick google search confirms it exists: a "step down" connector: https://www.waytekwire.com/item/38247/External-Step-Down-Butt-Connector-38247-/ . Considering the wire entering the gold connector would be perhaps 16 AWG and 16 AWG can handle (according to Google) 13A, would this be a reasonable alternative? Of course, it may not be feasible as I may not have the time available to wait for shipping.