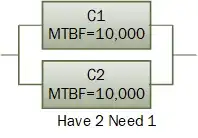

I'm calculating some ridiculous PFHD values for a Dual Redundant Self Checking Circuit and since I'm no expert in reliability calculations (cough) I wanted to check some of the logic.

I have two identical, but independent instances of the same circuit (C1 and C2) both being checked by a third checking circuit (C3). C3 only allows C1 and C2 to be reset if both C1 and C2 are in the tripped state when the Reset button is pressed. Using component FIT data and MIL-HDBK-217F I calculate the failure rate of each of C1 and C2 to be 1E-4/hour, so 100,000 FIT (dominated by a relay in each). C3 consists solely of logic ICs and passives and I calculate a failure rate below 100 FIT (1E-7 /hour).

The machine this controls can only run if both C1 and C2 independently allow it. Ignoring the Self Checking Circuit (C3), I calculate the probability of failure PFHD = 1E-4 * 1E-4 = 1E-8 /hour. That's impressive to say the least (SIL 4) and makes me nervous of the validity of my calculation already.

The trip rate is reasonably high and much higher than the rate at which a significant hazard is averted, so I presume that I can treat the Self Checking circuit (C3) as effective automatic self diagnosis.

For the system as a whole to fail, C1 and C2 both have to fail. But C3 would detect the point at which just one has failed and then the system would be taken offline and repaired. So, for Failure On Demand, C3 must have failed as well (as an aside, it would need to be before the first of C1 and C2). As the Self Checking circuit (C3) is independent, the Pr(failure) = Pr(failure without self checking) * Pr(C3 failure). So PFHD = 1E-8 * 1E-7 = 1E-15 /hour. You can probably see why I'm doubting my calculation as that is about once per 10 ages of the universe!