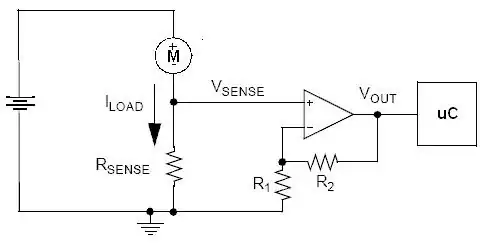

Attempting to measure latency on a photodiode.

This is the circuit I've put together: Source

- TS7805 to give my 5V (from a 12V rail)

- 1.2kHz square wave into first T1

- D1 is a BPW41

- scope on source and D1

- D1 driving base on another transistor rather than driving load directly

Output is as follows (blue - siggen, yellow - D1):

As CH1 rises past 0.7V you can see a ripple on CH2 but at this point the LED will have hardly come on, so this is presumably T1 opening -> voltage drop being compensated for by the 7805 causing this ripple?

And from these measurements it presumably remains impossible to measure what sort of latency D1 has, as I haven't taken account of the time it takes T1 to open and the LED to start emitting, right?

edit - thanks to u/WhatRoughBeast

I'd indeed vastly overcomplicated it, decided to isolate both sides as follows (source):

This gives a nice rise time ~7us across 3V (first screenshot, which makes sense now given the posted ~100us response time across 100V of the BPW41 per data sheet).

Curious about the ~200us time it takes for the voltage to fall though (second image), I can't see where there would be any capacitance in the circuit (if that's what it is?)