I have electromagnets I want to control using a Raspberry Pi. They run on 12V and each use 0.3A when briefly operating.

For various reasons I want to control the positive and negative sides of each magnet separately. I can achieve this using simple relays but wondered if I could use MOSFET drivers.

The website at http://www.gammon.com.au/motors has both high- and low-side MOSFET driver examples.

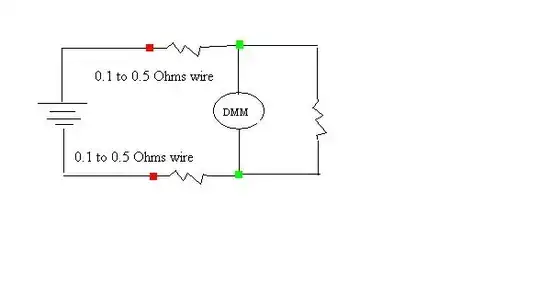

Would it be possible to have an arrangement (see below) which effectively combines a high- and low-side driver for the same load? I.e. the magnet would only operate if both the pins from the Pi are high.

(Diagram adapted from ones on the aforementioned website.)

Thanks.