I intend to use a safety relay for my project, however I found industrial safety relay mostly work with 24 VCC and is very big, so I decided to make a safety relay based on my specifications.

What I have learned yet is the safety relay have multiple input channel (series emergency buttons) with pair of the parallel relay in case of contact welded.

I think to detect the emergency bottom status with different locations (cable length) can use the opamp to measure its current.

There would be 3 possible states: short cut, open float, and connected.

When it is connected the current may change or set for 20 to 60 mA, so I decided to use comparator opamp to detect whether the current is out of the preset scope and if it is correct to enable the relay coil.

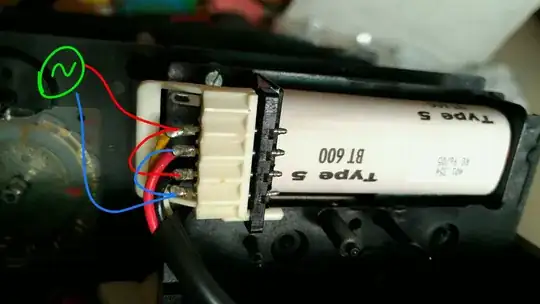

The following is my primary schematic for the safety relay however I couldn't figure out the whole connections.

Two series emergency buttons are connected through the shunt resistor, the first opamp convert this current to voltage, and the second opamp compare it giant the upper and lower limit and then enable the serial BJTs to enable the parallel relays. There are two buttons for starting and stopping the motor my question is does this schematic logic work? Is there any IC for monitoring the current is the specific upper and lower limit? Any tips are really appreciated.