I am looking for some advice on the direction of this project, I am a mech eng, who likes to tinker with electronics as a hobby.

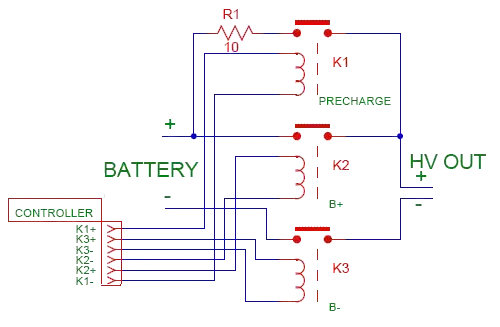

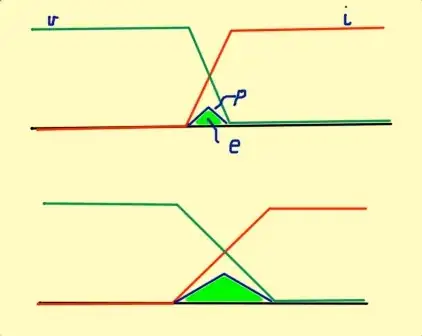

I want to build a on/off MOSFET switch for a 20s4p li-ion battery pack, including a pre-charge circuit to limit the inrush current and preventing sparking on the connectors.

Most of the examples I have found are only rated for 12s (50.4 V) batteries, but I need to switch ~84 V at 150 A continuous, ideally with the lowest possible leakage current in the off state to prevent draining the battery when not in use.

examples - https://github.com/msglazer/Anti-Spark_Switch

https://github.com/VinFar/High-Side-NMOS-Antispark-Switch

I would also like to implement a soft-start circuit to use a momentary push button, push to turn on, then push for 3 seconds to turn off.

Maybe also an auto switch off after 30 mins if no current has been drawn. I have looked at using an ATtiny with the sleep mode, which consumes very little power.

I am looking at using this Directfet - IRF7769L1TRPBF, putting a few in parallel to have a good headroom of current capability.

Any advise on how to design a circuit to switch 150 A at ~84 V and how to approach this would be great!

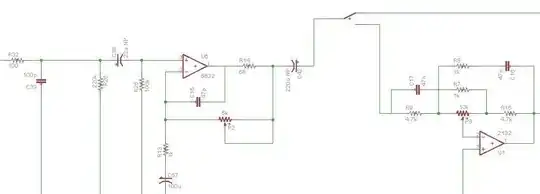

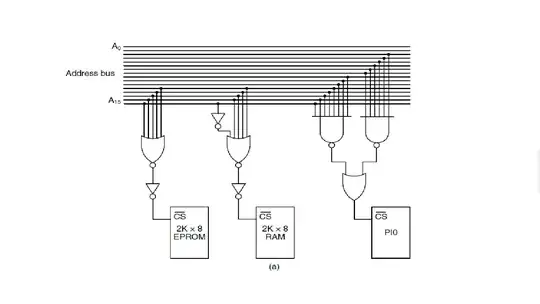

Edited with proposed circuit diagram without MCU control yet.

Edit 2

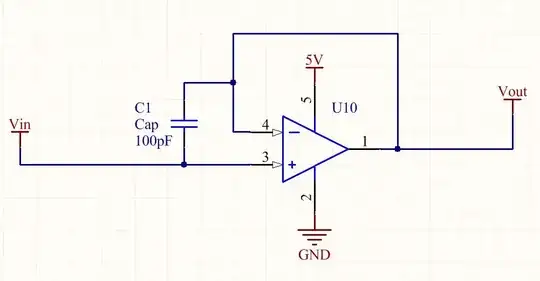

Replaced the toggle switch with push buttons. I found this LTC7001EMSE#PBF gate driver, which can work at over 100 V, so can I just use the main Batt voltage to drive the gate with this? It says it's a high side driver, will this work?