Some EV competitions require that 20% of the cells in a battery pack be monitored for temperature, and go on to strongly recommend that it be 100%. Considering that batteries can easily contain hundreds of cells, having an equal number of wires which have all to be connected to a board is somewhat burdensome. Not to mention having to have hundreds of ADC channels as well.

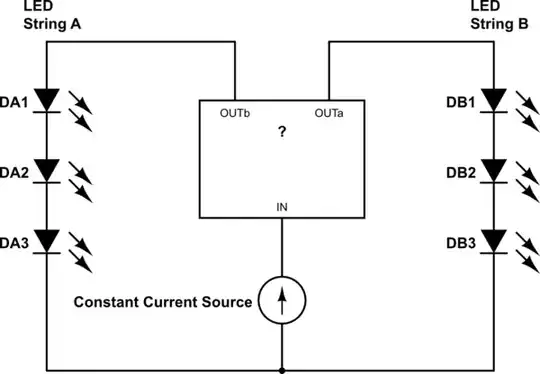

However, a resistor network could be used to greatly reduce the number of connections. Imagine a simple "square" network such as the below:

(Assume for the sake of argument that at least one of the resistors is a calibrated resistance so that the precise resistance can be determined, instead of just the relative resistance.)

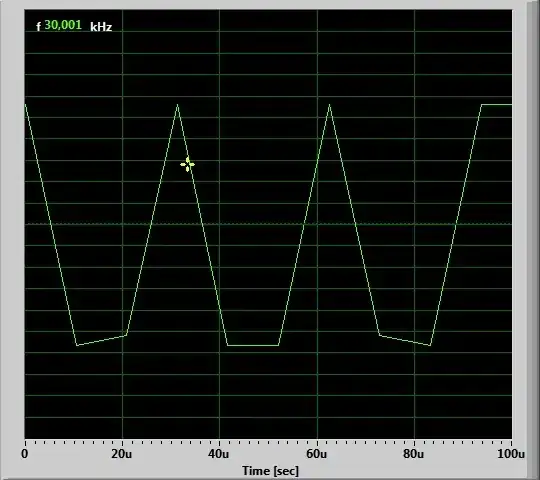

The switches would be controlled by a microcontroller so that they open and close appropriately to allow for measurements. For instance, in the above picture, the first measurement is identically 0V, because that leg is shorted to ground, but the other two measurements are functions of the individual resistance (as well as which input legs are turned on). So through all the permutations of the switches, a series of measurements can be made which would allow the system of simultaneous equations to be solved for the resistances, and thus the temperatures.

In a matrix approach such as the one above, the number of leg resistances which can be solved for is (INPUT! -1 ) * (OUTPUT! - 2), where ! is the factorial operator. In the above case, it's (3! - 1)*(3! - 2) = 5*4 = 20.

However, there are many interesting resistor networks, such as 2D triangles and 3D cube. Is there a straightforward way to determine the pros/cons of each topology? I don't have the mathematics worked out to validate this, but my hunch is that some topologies will be more sensitive to noise/failed sensors then others. I could also see optimizations which might be driven by which specific nodes in the circuit the ADCs are measuring. Furthermore, some topologies might be easier to solve for unknown resistances than others.

Simple simulation of the above square circuit.