The way the regulator sets the voltage is that it compares the fed-back voltage to an internal 1.25V reference.

For a regulator with R2 (upper) and R1 (lower) voltage divider, the output will be:

With the pot connected as shown effectively what is happening is the part 'below' the wiper is added to 820R as R1 and the part 'above' is R2. So with the wiper close to Vout, the output is 1.25V; with it close to R1 (820R), the max is whatever the regulator will let you do based on Vin.

It's a crappy design really, for several reasons.

- It doesn't set proper bounds on the adjustment.

- If the wiper gets dirty, while the pot moves the feedback pin can be disconnected briefly (like the 'crackle' in an audio pot) which will cause the output to spike to max voltage as you turn the pot.

As to the problem you're seeing, the panel pot may not achieve a full wipe range which is why the output adjustment isn't what you expect.

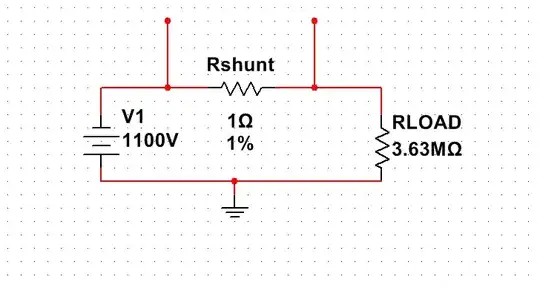

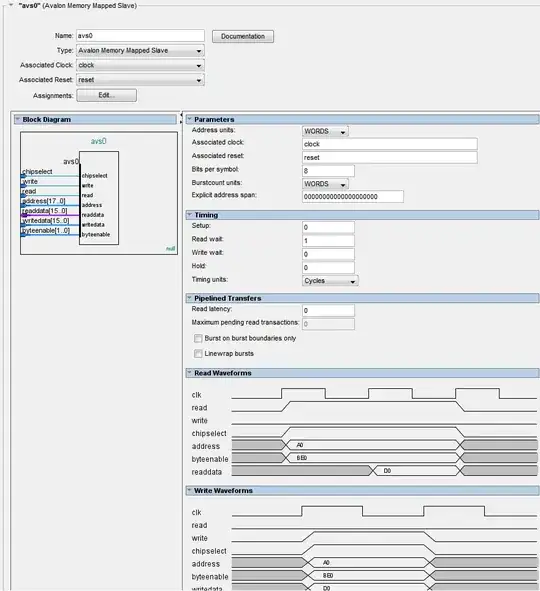

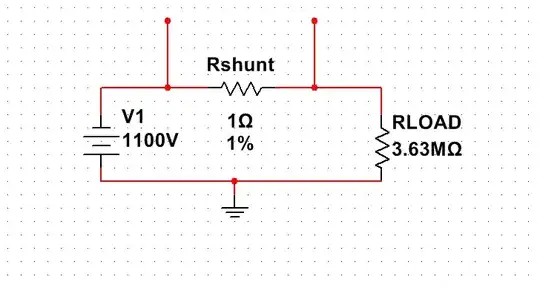

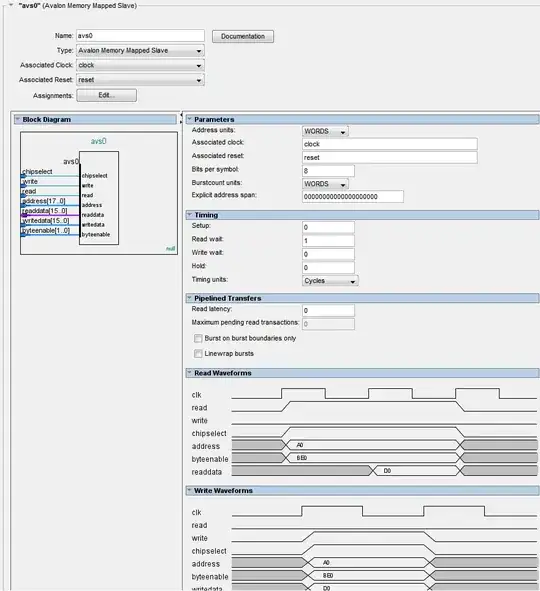

How to modify it with an external control? Here's a simulation, showing how you can patch into the feedback, safely. Simulate it here.

Design Notes:

- The op-amp models the feedback behavior.

- Uses 5k pot, with separate resistors that adjust the limits to be about 4V and 13V.

- I added a switch to each pot wiper to simulate a scratchy, failing pot. Watch what happens when each switch is opened.

I tried to reduce the resistor values to make the pot in the feedback loop less vulnerable to noise pickup. Nevertheless, you should consider running a shielded pair from the circuit to the front panel pot.

Here's how that would patch in to your existing PSU: